www.ptreview.co.uk

16

'26

Written on Modified on

MSK Finland improves efficiency with OLP and factory simulation

Virtual robot programming and intralogistics simulation from Visual Components cut programming time by 50% and enable data-driven automation planning.

www.visualcomponents.com

MSK Finland manufactures safety cabins for agricultural and logistics machinery. Operating a 60,000 m² production facility with around 200 employees, the company produces approximately 14,000 cabins annually and manages the full process from concept design to serial production. Due to the scale and complexity of its products, automation has been a core element of MSK’s production strategy since the early 1990s.

Today, the factory operates a diverse fleet of industrial robots from multiple suppliers across welding, grinding, painting, tube handling and material-handling processes. Maintaining a high level of automation is essential for MSK to remain competitive in high-volume, cost-sensitive markets.

Robot programming constraints and growing logistics complexity

Despite its long experience with robotics, MSK faced limitations that affected productivity. Robot programming was largely performed using teach pendants directly on the shop floor. This required stopping production during programming and commissioning, increasing downtime and tying up skilled resources. The challenge was particularly evident in complex multi-robot environments, such as synchronized welding cells, where programming accuracy and coordination are critical.

In parallel, internal logistics became increasingly demanding as production volumes grew. The factory handles thousands of material movements daily, including racks, pallets, painted components, subassemblies and empty carriers. Much of this transport relied on forklifts, and MSK needed to assess which flows could be automated using mobile robots without disrupting ongoing operations. The company required a reliable method to evaluate feasibility, routing and utilization before making investment decisions.

Virtual robot programming to reduce downtime and improve quality

To address robot programming challenges, MSK introduced robot offline programming software that allows robot programs to be created and validated in a virtual environment. Programming tasks are now performed on a computer rather than directly on the robot, enabling production to continue uninterrupted.

The virtual models are used to verify robot reachability, validate fixtures, remove unnecessary path points and test collision-free motion. As a result, typical programming time has been reduced by around 50%, depending on cell complexity. The benefits are most significant in multi-robot cells, where synchronized movements can be tested and refined before deployment.

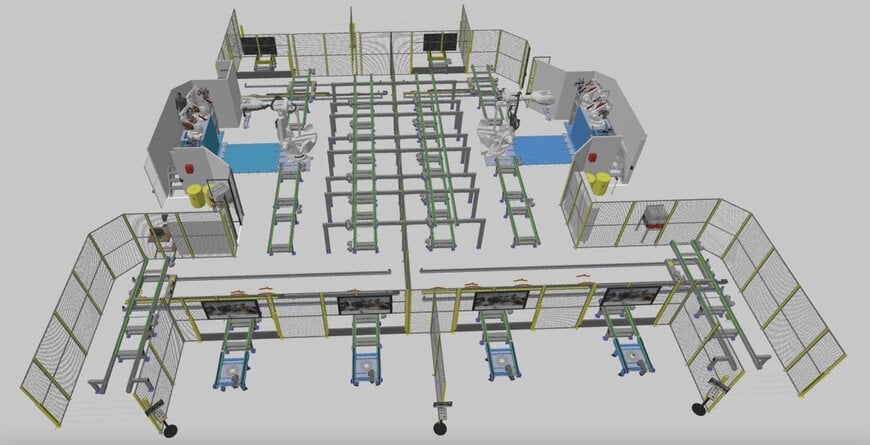

MSK now programs a wide range of robotic systems offline, including welding cells with gantries and positioners, synchronized multi-robot welding stations and grinding cells with multiple controllers. Several robot cells have been fully designed and programmed virtually before physical installation, shortening commissioning time and improving first-time success rates. Seam search routines can also be defined and tested in advance, reducing fine-tuning work on the shop floor.

Data-driven evaluation of intralogistics automation

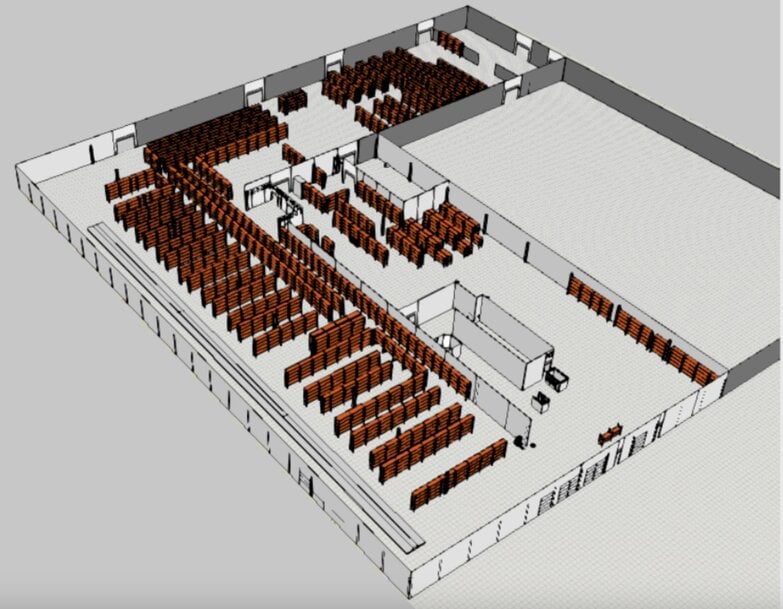

Alongside robot programming, MSK applied factory simulation software to study intralogistics automation. A detailed digital model of the factory was created using layout data, production volumes and real material flows. The simulation covered the movement of racks, pallets, painted parts and subassemblies, with each task modeled using realistic frequencies, routes and timing.

Mobile robot behavior was simulated using representative performance data, including driving speeds and interaction with human-operated forklifts. This allowed MSK to assess safety, routing constraints, buffer requirements and utilization rates without interrupting production.

The analysis showed that a stacker-type automated guided vehicle could reach a utilization rate of 68% over an eight-hour shift while handling the evaluated tasks. The results confirmed that mobile robots could be integrated effectively within the existing factory layout.

Faster commissioning and a foundation for future automation

The combined use of robot offline programming and manufacturing simulation has delivered measurable operational benefits for MSK. Robot programs are developed more efficiently and consistently, production downtime during programming has been eliminated, and collision risks are identified earlier in the design phase. Preparing robot programs before installation has shortened commissioning times and improved overall program quality.

For intralogistics, simulation has provided a structured, data-driven basis for automation decisions. MSK now has a clear understanding of which internal transport tasks are suitable for mobile robots and how these systems could scale in the future. The digital factory model also supports scenario analysis for layout changes, fleet expansion and integration with production IT systems.

Supporting long-term automation strategy

By establishing a virtual environment for both robot programming and logistics planning, MSK has created a scalable digital foundation for future automation investments. The approach supports continuous improvement in existing production processes while reducing risk when introducing new technologies. As MSK expands its use of advanced robotics and intralogistics automation, virtual design and simulation remain central tools for maintaining efficiency and competitiveness in serial production.

www.visualcomponents.com