CC-Link IE TSN enables millimetre-precise automation for steel mesh handling

Synchronized motion, vision, and safety control replace manual handling in a world-first system.

www.cc-link.org

Automation specialist Hambi Maschinenbau, part of Terhoeven GmbH & Co. KG, has developed a groundbreaking automated system for cutting, handling, and stacking heavy reinforcing steel mesh. By integrating advanced drive and control technologies from Mitsubishi Electric over the CC-Link IE TSN industrial Ethernet network, the solution achieves millimetre-level precision and seamless synchronisation across motion, safety, and vision—transforming a process that once required up to six operators into a fully automated workflow.

From manual handling to real-time automation

Reinforcing steel mesh production involves welding long wire lengths into large, heavy mats that must be accurately cut and stacked. Historically, this was a labour-intensive task: multiple operators were needed to lift, align, cut, and stack the flexible meshes, where even slight misalignment could cause defects or downtime.

Determined to automate this demanding process, steel processor Van Merksteijn International B.V. commissioned Hambi to design a system capable of detecting and compensating for alignment variations in real time. The result is the ASA (Automatic Cutting System)—a six-metre-high, 40-metre-long installation that automates every step, from lifting the top mat to cutting, turning, and compact stacking.

Precision through synchronisation

At the heart of the ASA system are six grippers, each with independent three-axis movement. As the mesh bends under its own weight during lifting, the grippers dynamically adjust to maintain uniform tension and prevent deformation. In total, 18 servo drives coordinate this motion, supported by additional drives for transport, turning, and stacking.

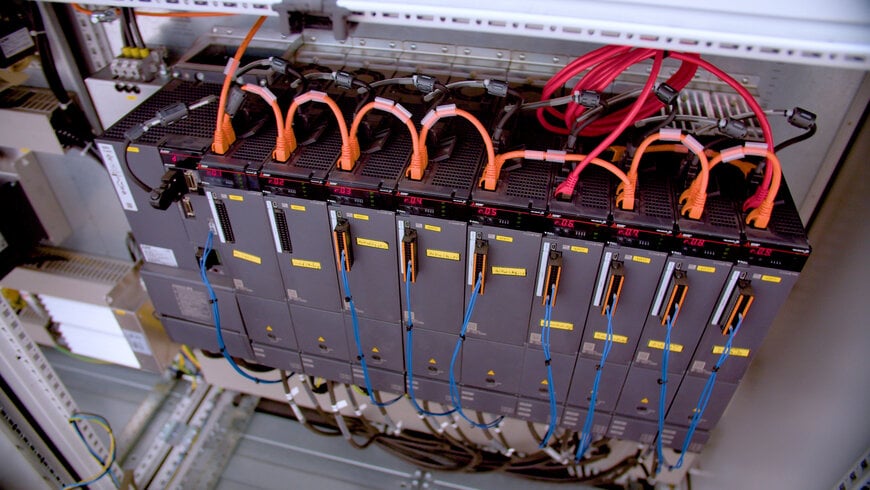

To keep all components perfectly aligned, Hambi connected servo drives, safety PLCs, frequency inverters, controllers, and the vision system via CC-Link IE TSN. The deterministic, gigabit-speed communication of this open Ethernet standard ensures precise time synchronisation, enabling accurate gripping and positioning even as the mesh naturally flexes.

“Communication via CC-Link IE TSN is particularly important,” explains Marc Orgassa, Managing Director of Orgassa GmbH, Hambi’s long-standing automation partner. “It ensures that controllers, drives, and image processing remain synchronised—essential when vision systems depend on the exact position of every gripper.”

CC-Link IE TSN's high-speed, deterministic communication allowed Hambi to achieve millimetre-level precision when gripping and positioning the steel mesh, even as it naturally bends and shifts during lifting.

A world-first in steel mesh handling

After two years of development, the ASA system was commissioned in spring 2024, delivering the precision, reliability, and productivity required for large-scale reinforcing steel production. By consolidating motion, safety, and vision on a single high-speed network, the solution simplifies system design while pushing automation performance to new levels.

“It’s inspiring to see machine builders like Hambi use CC-Link IE TSN to solve such complex motion control challenges,” says John Browett, General Manager of the CC-Link Partner Association – Europe. “Combining multiple control tasks on one open, high-speed network shows how this technology enables advanced automation without added complexity.”

www.cc-link.com