The global IO-Link market driven by the rise of automation

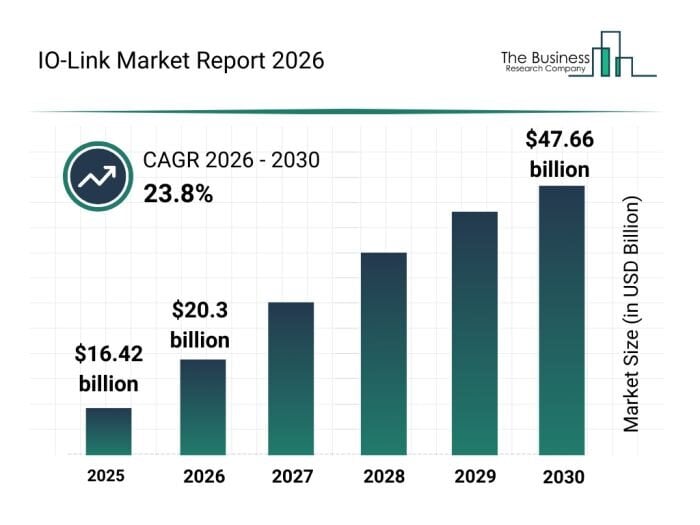

According to a study published by The Business Research Company, the global IO-Link market is experiencing sustained growth, driven by the expansion of industrial automation and connectivity technologies.

The market value is estimated at $16.42 billion in 2025 and is expected to reach $20.3 billion in 2026, representing a compound annual growth rate (CAGR) of 23.6%. Over the longer term, the report forecasts a market size of $47.66 billion by 2030, with a CAGR of 23.8% over the forecast period.

This growth is attributed to several factors, including the increasing adoption of standardised protocols for sensor communication, the early integration of IO-Link into machine tool automation, the development of modular actuator systems, and the wider deployment of industrial connectivity solutions. The need to simplify equipment commissioning and configuration is also contributing to this momentum.

Principles and key characteristics of IO-Link technology

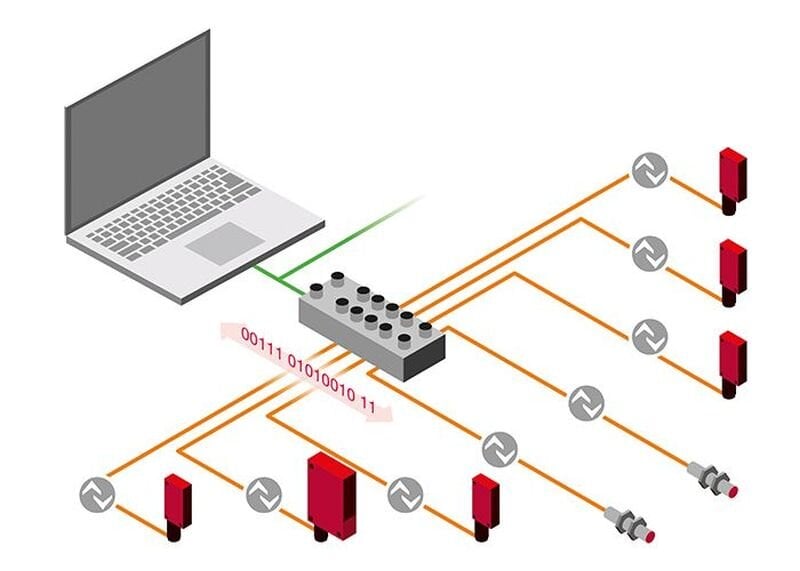

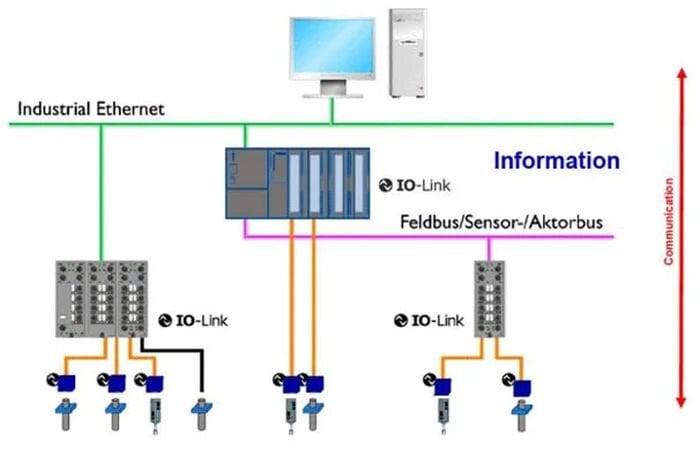

IO-Link is a standardised digital communication protocol (IEC 61131-9) designed to connect sensors and actuators to automation systems. It is based on point-to-point communication between an IO-Link master and field devices, using standard unshielded cables. This approach enables the transmission not only of process data, but also of configuration parameters, diagnostic information and device identification data.

One of the major advantages of IO-Link lies in the standardisation of the interface between field devices and controllers, regardless of manufacturer. This feature simplifies the integration of components into existing automation architectures.

Leuze IO-Link masters support Ethernet-based fieldbus protocols such as Profinet and Ethernet/IP, as well as Modbus TCP for communication with simpler programmable controllers, operator terminals or SCADA systems.

Benefits of IO-Link for deployment, operation and maintenance

During deployment phases, IO-Link enables centralised configuration of sensors and actuators from the control system, reducing the need for manual intervention in the field. Parameters can be saved and automatically restored when a device is replaced, helping to minimise downtime.

During operation, access to detailed diagnostic data improves visibility into equipment condition. Information such as thresholds, measurement drift or operational alerts can be leveraged by supervisory or maintenance systems.

From a maintenance perspective, IO-Link facilitates the implementation of preventive or condition-based strategies. Data collected at device level helps anticipate certain failures and plan interventions, in line with data-driven maintenance approaches.

Despite its advantages, IO-Link has certain technical limitations. The protocol is designed for point-to-point communication and does not support complex network topologies without the addition of intermediate IO-Link masters. Communication speeds are well suited to conventional sensors and actuators, but are not appropriate for applications requiring large data volumes or extremely short cycle times.

In addition, IO-Link does not replace higher-level fieldbuses or industrial Ethernet networks, but integrates as a complementary layer closest to the devices.

With its optional IO-Link communication interface, the PSD-4 electronic pressure switch from Wika can be integrated more quickly into PLC-based systems.

IO-Link is mainly used in industrial automation systems to connect position, pressure, temperature and flow sensors, as well as simple actuators. It is deployed in sectors such as discrete manufacturing, food processing, intralogistics, packaging, and automated production lines.

The report also highlights the growing role of IO-Link in Industry 4.0 environments, particularly in relation to connected sensors, remote diagnostics and integration with IoT platforms. The expected increase in the number of connected objects, estimated at 30 billion units by 2025 according to the World Economic Forum, further reinforces interest in standardised device-level communication technologies.

Geographical distribution of the market

In 2025, Europe is identified as the leading region in the IO-Link market, driven by a broad industrial base and a high level of automation. The report also covers Asia-Pacific, North America, South America, the Middle East and Africa, where IO-Link adoption is progressing in parallel with the development of industrial and digital infrastructures.

Article written by Youssef Belgnaoui, a journalist specialising in industrial technologies, based on data provided by The Business Research Company report