www.ptreview.co.uk

02

'26

Written on Modified on

Selecting the Right Three-Phase Transformer Configuration

A Practical Engineering Guide from Bel Fuse for Reliable Power Distribution.

www.belfuse.com

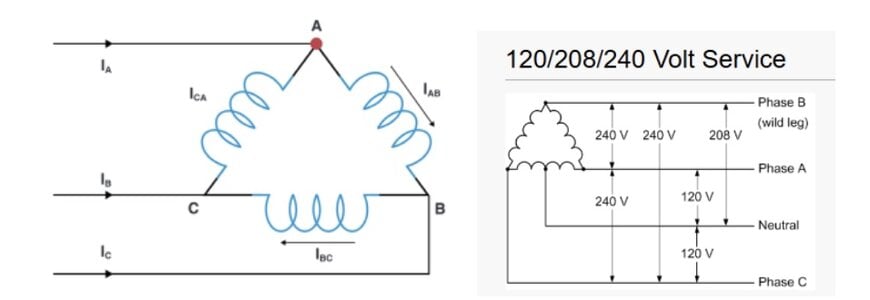

Delta connection schematic (left) and an example for a center-tapped configuration providing multiple voltage levels (right)

Choosing the correct three-phase transformer configuration is a foundational decision in power distribution design. Winding arrangements directly influence system reliability, load flexibility, grounding strategy, harmonic performance, and overall project cost. For industrial and commercial engineers, understanding how Delta and Wye configurations behave in real-world applications is essential to specifying transformers that perform as intended over their full service life.

At Bel Fuse, decades of transformer engineering experience show that optimal system performance is achieved not by defaulting to familiar designs, but by matching transformer configuration and cooling method precisely to the application’s electrical, environmental, and operational requirements.

Why Transformer Configuration Matters

In three-phase power systems, transformer winding arrangements determine how effectively the system handles unbalanced loads, supplies single-phase equipment, and manages grounding. The four standard configurations—Delta-Delta, Wye-Wye, Delta-Wye, and Wye-Delta—each present distinct electrical behaviors that can either enhance or limit system performance depending on the use case.

Compared with three individual single-phase transformers, a three-phase transformer built on a common core uses copper and steel more efficiently. This results in smaller size, lower weight, and reduced cost per kVA. These benefits, however, are only fully realized when the transformer configuration aligns with load characteristics and voltage requirements.

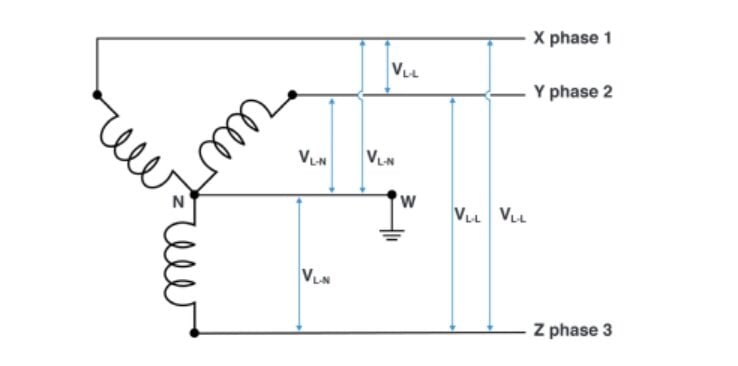

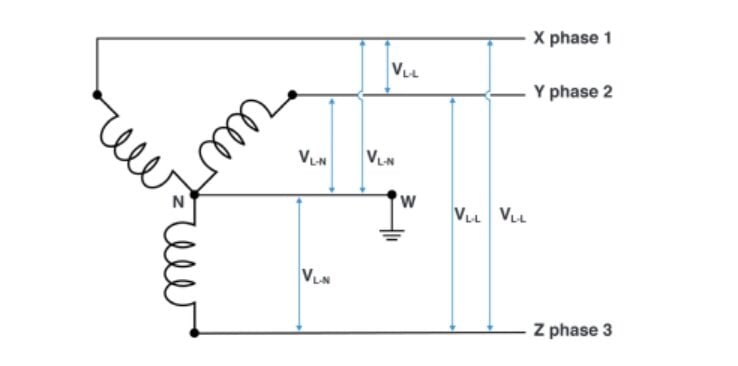

Wye connection schematic

Delta and Wye Fundamentals

Delta (Δ) Connections

Delta-connected windings form a closed loop without a neutral point. Line voltage equals phase voltage, and phase current is lower than line current by a factor of √3. This configuration is inherently robust when supplying large or unbalanced three-phase loads and provides good current balance on the source side.

While standard Delta systems do not provide a neutral, center-tapped Delta designs can offer multiple voltage levels and limited single-phase capability where required.

Wye (Y) Connections

Wye-connected transformers include a neutral point, creating a four-wire system. This allows a single transformer to supply both line-to-line voltage for three-phase loads and line-to-neutral voltage for single-phase equipment. The neutral point also simplifies grounding, making Wye connections well suited for mixed-load environments.

Comparing Common Three-Phase Configurations

Delta-Delta (Δ/Δ)

Delta-Delta transformers are valued for continuity of service. If one winding fails, the remaining two can continue operating at reduced capacity. This makes the configuration attractive for critical processes where downtime is unacceptable. However, the lack of a neutral limits flexibility, and higher winding counts typically increase cost.

Wye-Wye (Y/Y)

Wye-Wye configurations are economical and provide neutral connections on both primary and secondary sides. They support mixed single-phase and three-phase loads and have no phase shift, simplifying parallel operation. Careful load balancing is essential, however, as this configuration can transmit harmonic distortion between primary and secondary systems.

Wye-Delta (Y/Δ)

Common in step-down applications at transmission endpoints, Wye-Delta transformers benefit from reduced insulation requirements on the primary side. The grounded neutral improves safety in high-voltage installations. Designers must account for the inherent 30-degree phase shift and reduced fault tolerance.

Delta-Wye: The Preferred Industrial Standard

The Delta primary / Wye secondary (Δ/Y) configuration has become the dominant choice for industrial, commercial, and data-intensive facilities. The Delta primary presents a balanced load to the utility and effectively blocks third-harmonic currents, while the Wye secondary provides a neutral for mixed load distribution and grounding.

In manufacturing environments, Δ/Y transformers support three-phase motors alongside single-phase control systems. In data centers, they suppress harmonic distortion generated by UPS systems and server loads, preventing interference with upstream infrastructure. Commercial buildings rely on Δ/Y systems to distribute power efficiently to HVAC systems, lighting, elevators, and receptacle circuits from a single transformer.

Typical voltage combinations include:

Choosing the correct three-phase transformer configuration is a foundational decision in power distribution design. Winding arrangements directly influence system reliability, load flexibility, grounding strategy, harmonic performance, and overall project cost. For industrial and commercial engineers, understanding how Delta and Wye configurations behave in real-world applications is essential to specifying transformers that perform as intended over their full service life.

At Bel Fuse, decades of transformer engineering experience show that optimal system performance is achieved not by defaulting to familiar designs, but by matching transformer configuration and cooling method precisely to the application’s electrical, environmental, and operational requirements.

Why Transformer Configuration Matters

In three-phase power systems, transformer winding arrangements determine how effectively the system handles unbalanced loads, supplies single-phase equipment, and manages grounding. The four standard configurations—Delta-Delta, Wye-Wye, Delta-Wye, and Wye-Delta—each present distinct electrical behaviors that can either enhance or limit system performance depending on the use case.

Compared with three individual single-phase transformers, a three-phase transformer built on a common core uses copper and steel more efficiently. This results in smaller size, lower weight, and reduced cost per kVA. These benefits, however, are only fully realized when the transformer configuration aligns with load characteristics and voltage requirements.

Wye connection schematic

Delta and Wye Fundamentals

Delta (Δ) Connections

Delta-connected windings form a closed loop without a neutral point. Line voltage equals phase voltage, and phase current is lower than line current by a factor of √3. This configuration is inherently robust when supplying large or unbalanced three-phase loads and provides good current balance on the source side.

While standard Delta systems do not provide a neutral, center-tapped Delta designs can offer multiple voltage levels and limited single-phase capability where required.

Wye (Y) Connections

Wye-connected transformers include a neutral point, creating a four-wire system. This allows a single transformer to supply both line-to-line voltage for three-phase loads and line-to-neutral voltage for single-phase equipment. The neutral point also simplifies grounding, making Wye connections well suited for mixed-load environments.

Comparing Common Three-Phase Configurations

Delta-Delta (Δ/Δ)

Delta-Delta transformers are valued for continuity of service. If one winding fails, the remaining two can continue operating at reduced capacity. This makes the configuration attractive for critical processes where downtime is unacceptable. However, the lack of a neutral limits flexibility, and higher winding counts typically increase cost.

Wye-Wye (Y/Y)

Wye-Wye configurations are economical and provide neutral connections on both primary and secondary sides. They support mixed single-phase and three-phase loads and have no phase shift, simplifying parallel operation. Careful load balancing is essential, however, as this configuration can transmit harmonic distortion between primary and secondary systems.

Wye-Delta (Y/Δ)

Common in step-down applications at transmission endpoints, Wye-Delta transformers benefit from reduced insulation requirements on the primary side. The grounded neutral improves safety in high-voltage installations. Designers must account for the inherent 30-degree phase shift and reduced fault tolerance.

Delta-Wye: The Preferred Industrial Standard

The Delta primary / Wye secondary (Δ/Y) configuration has become the dominant choice for industrial, commercial, and data-intensive facilities. The Delta primary presents a balanced load to the utility and effectively blocks third-harmonic currents, while the Wye secondary provides a neutral for mixed load distribution and grounding.

In manufacturing environments, Δ/Y transformers support three-phase motors alongside single-phase control systems. In data centers, they suppress harmonic distortion generated by UPS systems and server loads, preventing interference with upstream infrastructure. Commercial buildings rely on Δ/Y systems to distribute power efficiently to HVAC systems, lighting, elevators, and receptacle circuits from a single transformer.

Typical voltage combinations include:

- 480/277 V (industrial, North America)

- 208/120 V (commercial)

- 600/347 V (Canada)

- 400/230 V (international)

Engineers must consider the 30-degree phase shift when paralleling transformers or supplying rectifier loads, as well as the reduced tolerance to single-winding failure compared to Delta-Delta designs.

Different types of transformers

Cooling Method Selection: Dry-Type vs. Liquid-Filled

Transformer cooling method is driven primarily by voltage level, power rating, and installation environment.

Dry-Type Transformers

Dry-type transformers use air for cooling and are commonly deployed indoors where fire safety and low maintenance are critical. Open-frame designs typically serve up to 1,000 V and 500 kVA, while cast-resin units extend to higher voltages and power levels. These transformers are ideal for hospitals, data centers, schools, and office buildings.

Liquid-Filled Transformers

Liquid-filled transformers use insulating oil to achieve higher power density and efficient heat dissipation. They are suitable for high-voltage and high-power outdoor installations but require additional safety measures, oil monitoring, and containment systems.

Engineering for the Right Outcome

Selecting the optimal three-phase transformer involves balancing electrical performance, grounding requirements, load diversity, environmental constraints, and lifecycle cost. Engineers should evaluate actual demand using diversity and utilization factors rather than relying solely on nameplate ratings to avoid unnecessary oversizing or performance limitations.

For many commercial and industrial applications, Delta-Wye dry-type transformers remain the preferred solution, offering flexibility, harmonic control, and safe grounding in a compact footprint.

Signal Transformer, a Bel Fuse brand, specializes in dry-type, open-frame three-phase transformers engineered for demanding power distribution environments. Backed by more than 50 years of transformer expertise, Bel Fuse delivers reliable, cost-effective solutions tailored to modern industrial and commercial power systems.

Learn more about Bel Fuse three-phase transformer solutions

www.belfuse.com

Different types of transformers

Cooling Method Selection: Dry-Type vs. Liquid-Filled

Transformer cooling method is driven primarily by voltage level, power rating, and installation environment.

Dry-Type Transformers

Dry-type transformers use air for cooling and are commonly deployed indoors where fire safety and low maintenance are critical. Open-frame designs typically serve up to 1,000 V and 500 kVA, while cast-resin units extend to higher voltages and power levels. These transformers are ideal for hospitals, data centers, schools, and office buildings.

Liquid-Filled Transformers

Liquid-filled transformers use insulating oil to achieve higher power density and efficient heat dissipation. They are suitable for high-voltage and high-power outdoor installations but require additional safety measures, oil monitoring, and containment systems.

Engineering for the Right Outcome

Selecting the optimal three-phase transformer involves balancing electrical performance, grounding requirements, load diversity, environmental constraints, and lifecycle cost. Engineers should evaluate actual demand using diversity and utilization factors rather than relying solely on nameplate ratings to avoid unnecessary oversizing or performance limitations.

For many commercial and industrial applications, Delta-Wye dry-type transformers remain the preferred solution, offering flexibility, harmonic control, and safe grounding in a compact footprint.

Signal Transformer, a Bel Fuse brand, specializes in dry-type, open-frame three-phase transformers engineered for demanding power distribution environments. Backed by more than 50 years of transformer expertise, Bel Fuse delivers reliable, cost-effective solutions tailored to modern industrial and commercial power systems.

Learn more about Bel Fuse three-phase transformer solutions

www.belfuse.com