www.ptreview.co.uk

12

'25

Written on Modified on

IO-Link Safety Devices Expand Functional Safety Capabilities

Schmersal introduces IO-Link Safety hardware designed to support interoperable machine safety and simplify data-rich industrial automation architectures.

www.schmersal.com

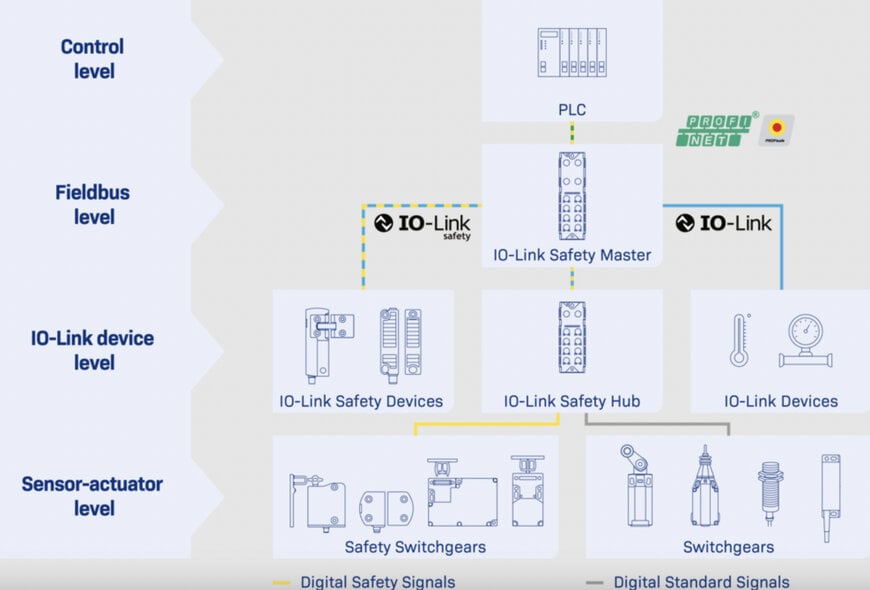

IO-Link Safety extends standardized, bidirectional communication to safety-related components in factory automation, enabling higher diagnostic transparency and functional safety performance across machinery and production lines.

Expanding Functional Safety in Industrial Automation

IO-Link Safety adapts the established IO-Link communication framework to safety applications by adding deterministic, safety-rated data exchange down to the field level. This allows safety devices to communicate process data, diagnostics, and status information through a uniform interface rather than through isolated, hardwired channels. For industries such as machine building, materials handling, automotive production, and complex digital supply chain environments, the approach supports scalable, modular safety architectures.

The standard delivers Performance Level e (PL e) in accordance with EN ISO 13849-1 and Safety Integrity Level 3 (SIL 3) according to IEC 61508/62061. It is defined internationally through IEC 61139-2, which establishes interoperability requirements so that safety components from different manufacturers can operate within the same system architecture. This interoperability is central to building an automotive data ecosystem or any environment where multi-vendor integration and machine connectivity are required.

According to Volker Heinzer, Strategic Product Manager for Industrial Communication and Industry 4.0, the interface combines functional communication and safety communication on one channel, enabling more transparent and data-driven machine safety strategies.

Device-Level Implementation: AZM42 and RSS362

Schmersal’s first IO-Link Safety products include the AZM42 solenoid interlock and the RSS362 safety sensor. Both devices support secure bidirectional data flow and provide real-time information needed for preventive diagnostics and configuration management.

The AZM42 adds comprehensive diagnostic reporting—such as supply voltage levels, temperature conditions, and RFID signal quality—and maintains a compact enclosure suited for machine guarding applications. The RSS362, a non-contact safety sensor, extends these diagnostic capabilities while enabling flexible mounting and wear-free operation.

Each device connects using standard three-wire cables with M12 connectors, reducing installation time compared with conventional safety wiring. The architecture supports data storage and offline configuration, allowing machine builders to pre-parameterize devices for series production and enabling maintenance teams to quickly restore configurations after replacements or retrofits.

Enabling Data-Driven Smart Factory Safety

IO-Link Safety supports the shift toward intelligent and self-monitoring safety systems in smart factories. By placing safety-rated communication on the same platform as functional machine data, operators gain faster fault localization, clear diagnostic visibility, and the ability to adapt safety functions to changing production requirements.

For machine builders, the technology lowers commissioning effort and simplifies multi-vendor integration. For operators, it provides a structured data pathway that strengthens predictive maintenance strategies and reduces downtime.

The introduction of the AZM42 and RSS362 demonstrates how IO-Link Safety is transitioning from an emerging specification to an applied industrial technology, positioned to shape next-generation safety architectures and support increasingly automated production systems.

www.schmersal.com