Expanded single-axis robot configurations for clean manufacturing

Yamaha Robotics extends the Robonity series to address long-stroke, high-speed transfer, and space-constrained automation requirements.

www.yamaha-motor.com

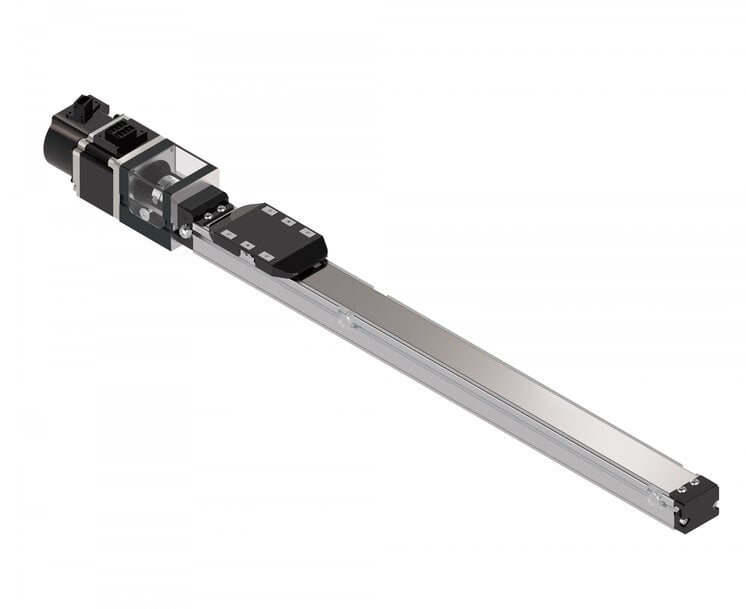

Yamaha Robotics has expanded its Robonity series of single-axis robots and motorless actuators with three new variants designed for long-stroke motion, high-speed transfer, and low-profile installations in clean and dry manufacturing environments.

Manufacturing context and application drivers

Production environments across automotive, electronics, and battery manufacturing are increasingly characterized by shorter product life cycles, higher product density, and greater variation in production volumes. These trends place pressure on automation systems to deliver higher throughput, flexible layouts, and rapid reconfiguration while maintaining accuracy and cleanliness.

In particular, the expansion of electric vehicle battery manufacturing has increased demand for linear transfer systems capable of operating in low dew-point, low-dust environments with constraints on copper usage and corrosion resistance. The Robonity series, introduced in 2019, was developed to address these requirements through a modular approach that allows users to select either motorized single-axis robots or motorless actuators depending on system architecture.

Long-stroke variant for high payload positioning

The newly introduced long-stroke type extends the Robonity series to a maximum stroke of 3,000 mm while supporting payloads up to 200 kg and repeatability of ±0.01 mm. A key technical element is Yamaha’s patented Optimal Support Mechanism, which uses multiple support points along the ball screw to suppress vibration and resonance associated with critical speed effects.

In conventional long-stroke designs, ball screw deflection at higher speeds can lead to resonance and reduced accuracy, often referred to as the “jumprope effect.” By stabilizing the screw across its length, the Optimal Support Mechanism enables operation at speeds up to 2,400 mm/s across a wide stroke range. This represents a significant increase compared with earlier Yamaha long-stroke designs, which were limited to approximately 1,200 mm/s.

An integrated guide rail and frame structure provides high moment rigidity in a compact form factor, supporting horizontal payloads of 200 kg and vertical payloads of 100 kg when paired with a 750 W motor.

Timing belt drive variant for high-speed transfer

The timing belt drive type targets applications requiring rapid transfer over long distances between production stages. It achieves a maximum stroke of 4,000 mm and a maximum speed of 3,750 mm/s, the highest transfer speed specified to date within Yamaha’s single-axis lineup.

This performance is enabled through increased motor output and a high-lead mechanical design. With a 400 W motor, the system can transport payloads up to 60 kg at maximum speed. Compared with previous belt-driven models, the extended stroke length enables greater layout flexibility for large-scale production equipment.

Low-profile variant for equipment downsizing

The low-profile type addresses space constraints in compact equipment designs. By integrating guide rails into a low-profile aluminum frame with an outer-rail configuration, the overall height has been reduced by approximately 20–46% relative to previous models.

Despite the reduced form factor, rigidity has been increased to approximately twice that of earlier designs in pitching, yawing, and rolling directions. The system achieves repeatability of ±0.005 mm and running accuracy of ±0.02 mm per 800 mm, supporting precise positioning in applications where vertical clearance is limited.

Clean environment compatibility and common features

All three new variants are designed for use in clean manufacturing environments. Protective shutters are fitted as standard to cover guide rails, ball screws, and belts, reducing grease dispersion and limiting the ingress of foreign matter. These measures support deployment in semiconductor and EV battery production lines where air purity and dry conditions are required.

Across the expanded lineup, users can select from a wide range of lead options, stroke lengths, and mounting orientations, including vertical and wall-mounted configurations. This configurability allows the Robonity series to be adapted to diverse automation architectures while maintaining consistent mechanical and environmental performance.

Lineup expansion and system integration

With the addition of the long-stroke, timing belt drive, and low-profile variants, the Robonity series now comprises 54 models. This expansion broadens the selection space for engineers designing positioning and material transfer systems across industries such as automotive components, electrical and electronic manufacturing, and consumer goods production.

By extending stroke length, transfer speed, and form factor options while maintaining compatibility with clean environments, Yamaha Robotics positions the Robonity series as a modular foundation for scalable factory automation systems aligned with evolving manufacturing requirements.

www.yamaha-motor.com