www.ptreview.co.uk

15

'25

Written on Modified on

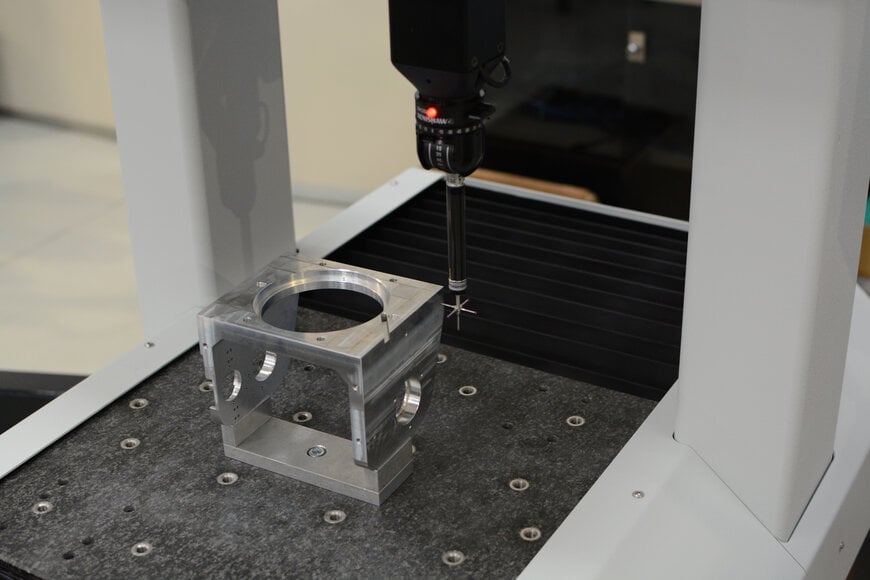

RUN – Flexible CMM Solutions for the Production Environment

Combining precision, robustness, and ease of use, Ready’s RUN systems deliver metrology-grade results directly on the shopfloor, enabling fast inspection, feedback, and control at every stage of production.

readymetrology.com

RUN is Ready’s answer to the evolving needs of modern manufacturing — a line of coordinate measuring machines designed specifically for use in production. Combining precision, robustness, and ease of use, RUN systems deliver metrology-grade results directly on the shopfloor, enabling fast inspection, feedback, and control at every stage of production.

Measurement Simplified

Developed with a clear goal — to make measurements simple, fast, and reliable — RUN systems integrate seamlessly into production workflows.

Linear motors guarantee maintenance-free operation, eliminating the need for air supply or lubrication, and ensuring long-term reliability even in challenging environments.

Ease of Use, Built In

Ease of operation is at the heart of RUN’s design. The Easy Runner interface allows operators to load and execute inspection programs with a single touch. while the moving table and optional clamping kit ensure quick and ergonomic part handling. Robot integration is facilitated by the moving table structure: both portal and measuring head are always out of the moving range, increasing safety during set up procedures and allowing faster part loading. Switching from one part to another takes only seconds also for the operator — simply scan a barcode to load a new program, and the machine performs measurement and reporting automatically.

Precision That Lasts

RUN systems include advanced features that enhance performance and longevity, such as:

• Automatic stylus cleaning unit

• Active anti-vibration granite base with pneumatic dampers

These elements guarantee accuracy and repeatability, even under real shopfloor conditions.

From Inspection to Optimization

Designed for both end-of-line control and in-process verification, RUN delivers immediate measurement data to help manufacturers prevent deviations, reduce scraps, and shorten setup times.

Integrated CAD import and GD&T analysis provide complete insight into part geometry, ensuring compliance with specifications and accelerating process improvement.

A Smarter Kind of CMM

With RUN, Ready expands the concept of what a CMM can be — a flexible, intelligent tool for every production team.

It’s not just a measurement system, but a production resource — transforming metrology from a back-end validation step into an active driver of manufacturing performance.

www.readymetrology.com