www.ptreview.co.uk

13

'26

Written on Modified on

Modular EtherCAT I/O with Enhanced Diagnostics

Beckhoff expands its distributed I/O portfolio with a new housing format, tool-free wiring, and app-based diagnostics for industrial automation.

www.beckhoff.com

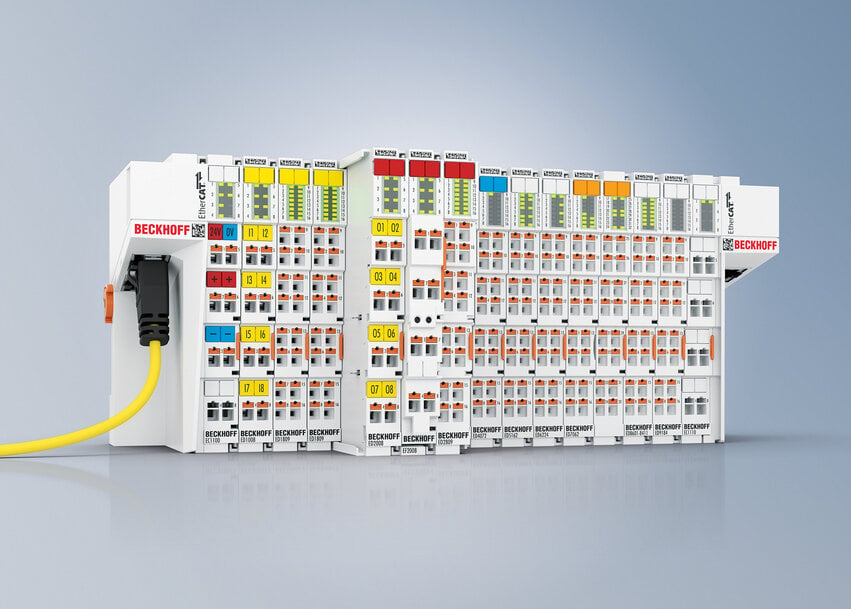

Beckhoff has introduced the ED series EtherCAT Terminals, a new generation of DIN rail-mounted I/O modules designed for distributed control architectures in industrial automation. The IP20-rated terminals retain compatibility with existing Beckhoff EtherCAT hardware while introducing a revised housing format, push-in wiring technology, and extended diagnostic features.

Continuity Within the EtherCAT Portfolio

Since 2003, EtherCAT Terminals have formed the core of Beckhoff’s modular I/O system. The ED series maintains full functional compatibility with installed EtherCAT infrastructure, allowing integration into existing automation systems without changes to communication architecture.

Internally, the ED terminals provide the same performance level and diagnostic capabilities associated with the EtherCAT platform. EtherCAT’s deterministic real-time communication supports precise signal acquisition and synchronization across distributed devices, which is essential for motion control, process automation, and high-speed manufacturing applications.

By preserving protocol consistency and mechanical interoperability, the new series supports long-term system scalability and investment protection.

Mechanical Design and Installation Efficiency

The ED series features a redesigned housing optimized for DIN rail mounting. Electrical connection is implemented via push-in wiring terminals, eliminating the need for tools during installation.

Push-in technology reduces wiring time and supports consistent contact quality, which can lower installation errors in control cabinets. For machine builders and panel integrators, simplified wiring and mounting can shorten commissioning cycles and reduce labor effort during both initial setup and retrofit projects.

The compact housing format supports high I/O density within limited cabinet space, a common requirement in modern machine design.

Integrated Diagnostics and Traceability

A distinguishing feature of the ED terminals is the inclusion of a scannable product data matrix code. This enables app-based access to product-specific information and diagnostic data, supporting faster identification during commissioning and service.

Built-in diagnostics monitor signal states and device conditions directly within the EtherCAT network. Combined with digital traceability, this facilitates fault localization and spare parts management in large-scale installations.

Simplified troubleshooting contributes to reduced downtime and improved system availability, particularly in production environments where distributed I/O nodes are deployed across multiple machines or process stations.

Application in Distributed I/O Architectures

The ED series is designed for use in factory automation, machine building, and process control systems requiring modular and scalable I/O. Flexible hardware integration allows configuration across a broad range of signal types while maintaining a consistent communication backbone.

By combining mechanical redesign, tool-free wiring, and extended diagnostics within an established EtherCAT framework, the ED series expands the functionality of Beckhoff’s distributed I/O platform. The result is a cost-efficient solution that maintains performance and compatibility while addressing installation efficiency and lifecycle management requirements in modern automation systems.

www.beckhoff.com