www.ptreview.co.uk

30

'19

Written on Modified on

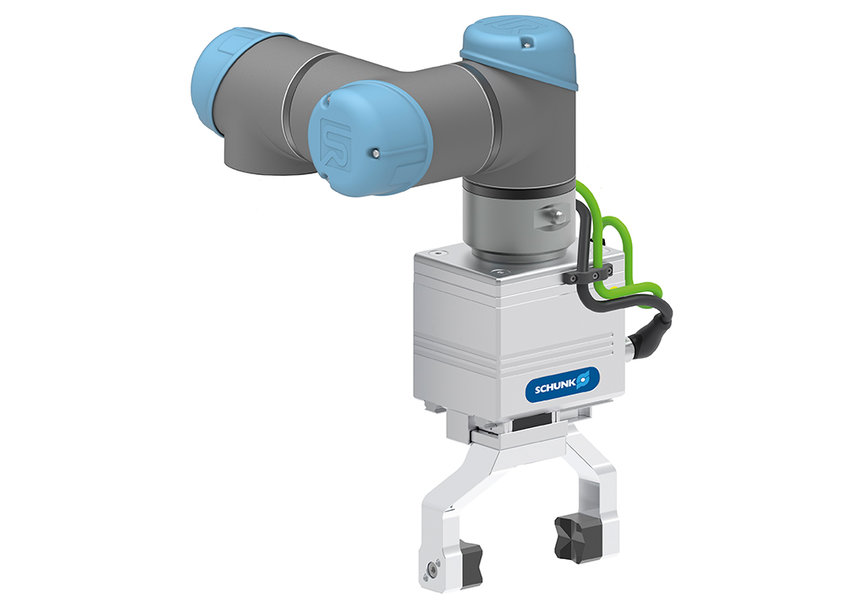

SCHUNK has increased its Plug & Work portfolio for Universal Robots by sensitive long-stroke grippers for automated machine loading

For the first time ever, SCHUNK is offering a robust mechatronic long-stroke gripper for machine tool loading specifically for the lightweight robots of Universal Robots CB and e series. The gripper stroke of 42.5 mm per finger is freely programmable and makes variable gripping forces between 50 N and 600 N possible.

In view to Universal Robots’ robot arms, SCHUNK defines a new benchmark in terms of flexibility, force, and functionality in clean to harsh environments with the Plug & Work capable gripper. The force-fit, intelligent gripper can handle various parts of up to 3 kg in alternation process-reliably: parts that are sensitive to deformation as well as heavy ones. A solid aluminum housing, stable guides, and a brushless servomotor ensures high robustness, consistent gripping forces over the entire stroke range, and reliable operation requiring minimum maintenance effort. In the event of a power failure, the electronically activated brake ensures that the position of the gripper fingers is held, and no referencing is necessary.

Minimum commissioning effort

The EGL starter kit from SCHUNK comprises of the intelligent servo gripper with matching adapter plates, cables, standard parts, as well as URCaps plug-in that radically simplifies programming of the mechatronic powerhouse. By using smart and easy-to-understand functions on the familiar UR interface and preconfigured parameters, the gripper can be commissioned and programmed within 15 minutes. On request, the starter kit is also available including universal gripper fingers and clamping inserts. This starter kit allows an especially rapid entry into the machine tool loading with lightweight robots from Universal Robots. Compared with conventional grippers, the effort for engineering, commissioning, and programming reduces from one to two days to less than 60 minutes.

The full range of gripping systems

The SCHUNK Plug & Work portfolio for Universal Robots comprises grippers for collaborative operation, pneumatic and electric grippers, sensor systems, and change systems. With maximum gripping forces between 140 and 930 N, and strokes between 6 and 42.5 mm it covers various fields of applications in conventional automation, but also in the field of collaborative applications. The range of gripping systems is suitable for beginners in the field of automation, and for experts in metal cutting, automotive, as well as electronics industry; and for many other industries that want to open the potentials of automation with UR robots. From the gripper to quick-change systems up to force/torque sensors, every interface is readily matched to each other. URCaps plug-ins additionally facilitate programming.

www.schunk.com