Voith and PTS Heidenau set a new standard for measuring stickies and non-tacky contaminants using near-infrared measuring technology

In collaboration with the research and service institute Papiertechnische Stiftung (PTS) Heidenau in Germany, Voith is introducing a new measuring method to detect unwanted tacky contaminants known as stickies.

Compared to established methods in the paper industry, the measuring technology uses NIR to determine more comprehensive information about the contaminants with a high measuring accuracy.

- New near-infrared measuring technology offers higher measuring accuracy and a wider range of applications compared to conventional measuring methods

- Reliable detection of stickies and non-tacky contaminants

- Voith, PTS Heidenau and PROPAKMA publish technical rule for sticky measurements as DIN SPEC 6745

The measuring method, which uses a near-infrared (NIR) camera, allows the reliable detection of contaminants along the papermaking process and offers higher measuring accuracy and a wider range of applications compared to conventional methods. The associated technical rule was recently published as DIN SPEC 6745.

Higher measuring accuracy and wider range of applications

Compared to established methods in the paper industry, the measuring technology uses NIR to determine more comprehensive information about the contaminants with a high measuring accuracy. The spectral measurements obtained are compared and assigned to values of known contaminants. This allows further classification of the contaminants based on their chemical composition. In addition, both adhesive and non-tacky contaminants can be identified and classified using the NIR measuring technology.

Reliable identification, reduced laboratory effort

The new measuring method enables much more reliable information to be obtained while reducing the amount of laboratory work involved. “Using NIR technology to measure stickies allows the papermaker to determine sticky balances with reliable and sufficient accuracy based on single measurements,” says Dr. Linus Friedrich, Senior Manager R&D Fiber Systems at Voith Paper. “This demonstrates one of the benefits of the new measurement technology. With conventional methods, this was only possible to a limited extent due to the large variation in results,” Friedrich said.

Since the new measuring method uses laboratory sheets that can be produced by a laboratory sheet former and contain fibers, stickies and non- tacky contaminants, numerous intermediate steps in sample preparation are eliminated. For example, the sticky contaminants in a stock sample no longer need to be concentrated in order to be analyzed. The preparation time for laboratory sheet formation is significantly shorter and the measurement is less prone to error than applying conventional methods. Moreover, the new NIR measuring method can be used to evaluate final paper samples in addition to stock samples.

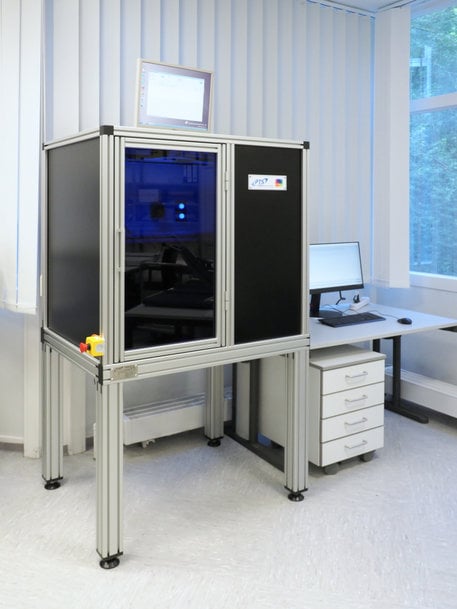

A near-infrared camera detects stickies and non-tacky contaminants reliably and accurately.

Technical rule published as DIN SPEC 6745

The technical rule developed in cooperation with Papiertechnische Stiftung (PTS) Heidenau and PROPAKMA was recently published as DIN SPEC 6745. The DIN SPEC is a preliminary stage of the DIN standard and describes the measuring procedure based on NIR measuring technology. The DIN SPEC 6745 is available to download free of charge from the Beuth Verlag website.

A new standard for the paper industry

Thanks to its technological advantages, the NIR measuring technology has the potential to replace established methods for measuring stickies. The publication of a technical rule on sample preparation and the performance of measurements has created the underlying conditions for setting a new standard in the paper industry.

The new measuring technology is available at the Voith Paper Technology Center in Heidenheim for the technology group’s R&D activities and for customer trials. This innovation can also be used, e.g., in service operations and customer audits. Voith is the first company in the paper industry to make use of the measuring device developed by PTS Heidenau and thus, as a full-line supplier to the paper industry, contributes significantly to an ever better understanding and analysis of the entire paper manufacturing process through intensive research and development activities.

www.voith.com