www.ptreview.co.uk

23

'21

Written on Modified on

Efficient device cooling on the circuit board (FLKU 10)

Electronic devices that are installed directly on the circuit board require an adapted thermal management depending on the device size and the power loss to be dissipated.

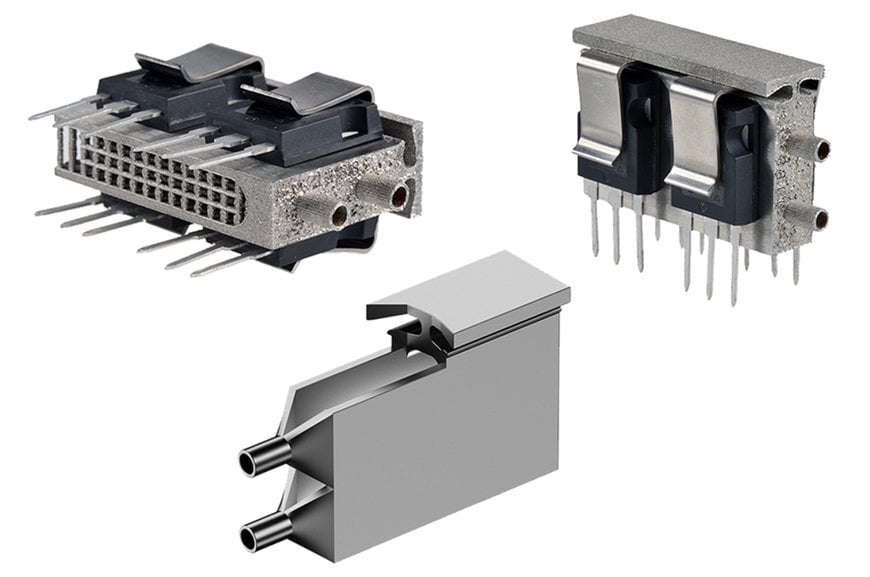

Higher power losses of the electronic devices also mean more stress and strain which can directly lead to a reduction in device life in the respective application or even to functional failures of the entire system. In addition to intelligent circuit concepts with a sensible selection of devices, efficient cooling concepts for the PCB are of essential importance. Fischer Elektronik GmbH & Co. KG is now offering a newly developed fluid heatsink for the PCB especially for the heat dissipation of larger power losses from electronic components. The item FLKU 10 is designed and structured for cooling the most common power semiconductors in TO cases and many more, such as TO 220, TO 218, TO 247, TO 248, various SIP Multiwatt, perforated MAX types.

The new type of fluid heatsink FLKU 10 is made of a stainless austenitic steel (V4A) using a 3D printing process and contains a separate cooling circuit on each assembly side. The semiconductor mounting surfaces are finely polished with very good flatness and low surface roughness and they also guarantee the smallest heat transfer resistance between the device to be cooled and the fluid heatsink. Due to the material used the cooling medium water can be used with a maximum operating pressure of 3 bar without any corrosion protection inhibitors. The geometry and contour of the heat exchange structure integrated in the cooling circuit is optimally designed and developed in terms of heat and flow using artificial intelligence (AI).

The additive production process enables a very compact heatsink design and the heat dissipation of large amounts of heat with little space requirement. The safe semiconductor assembly or fastening on the fluid heatsink is carried out in connection with so-called snap-in transistor retaining springs made of stainless steel from the THFU series, which can be clipped directly into a groove geometry which is integrated in the heatsink. Once snapped in place, the spring holds it immovably and cannot be lost in its position and fixes the respective transistor on the mounting surface with high pressure. The position of the lock-in retaining spring for transistor cannot be displaced in the longitudinal direction and falling out in the transverse direction is not possible.

Suitable liquid pumps and hose systems, other materials with a higher thermal conductivity, designs with soldering for direct circuit board mounting as well as geometrical adjustments based on specified installation conditions are specified and offered on customer request.

Fischer Elektronik's core competences also include surface coating, so that further mechanical processing such as hole patterns and distances, thread types and sizes, surfaces in black anodised or electrically conductive in transparent passivated as well as several pressed-in wire form springs for increasing the holding force can be realised according to customer specifications.

www.fischerelektronik.de