www.ptreview.co.uk

22

'23

Written on Modified on

New SEEPEX Pump Tailored to the Battery Industry

For the highly complex manufacturing process with all its technological challenges, SEEPEX stands by manufacturers with the precise performance of its specialized pumps.

Rechargeable batteries ensure that the power in electric vehicles, smartphones, notebooks and many other applications lasts. Gigafactories are being built around the world to meet the huge demand for lithium-ion batteries in the automotive, electronics and semiconductor industries.

SEEPEX pumps and pumping solutions compliment the battery manufacturing process from start to finish. They are used in raw material processing, electrode material production, film and cell production and battery recycling. The progressive cavity pumps convey binders, additives and active ingredients in perfect doses. The company also supplies pumps for the efficient production of electrode pastes. "As a globally sought-after specialist for progressive cavity pumps, pump systems and digital solutions, SEEPEX is helping to make the transition to greater sustainability a success," says Thomas Dufner, Battery Market Manager at SEEPEX.

New range in response to customer demands

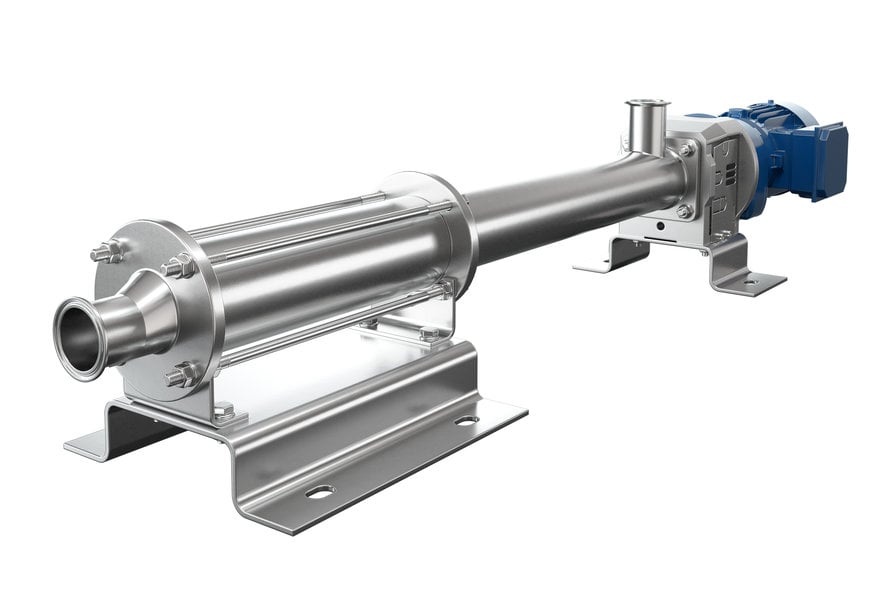

With the new BF range and its exceptional advantages, SEEPEX recommends itself as a reliable partner for the battery industry. The new pump can be installed quickly, has a flow rate of up to 30 m³/h and operates at a pressure of up to 12 bar. It is available in block or bare shaft design and can meet customer-specific drive requirements. A TA-Luft or ATEX certified version is also available.

A great deal of data analysis and customer input went into the highly optimized development of this latest generation of pumps. After all, battery production is full of challenges. Chemical resistance and chemically compatible materials are required to avoid contamination of valuable raw materials. During the critical process of formulation, continuity and high repeatability are essential. Contamination-free pumps are also essential for smooth operation. The coating process plays another important role, as the pump has a direct impact on product quality by minimizing variations in coating thickness. Finally, investment and operating hour costs should be kept as low as possible.

Reduce maintenance time and total cost of ownership

The SEEPEX BF pump is precisely tailored to these requirements; ensuring safety, cleanliness, high product quality and, last but not least, cost efficiency. The precise performance provides high quality support to the production process. The maintenance-friendly design reduces downtime and the total cost of ownership (TCO). The clamp connections for quick installation/removal and the removable rotating unit simplify replacement and maintenance work. Due to SEEPEX’s focus on sustainability, with proper maintenance the robust pump has a long product life.

SEEPEX BF: Safe, Clean, Stainless

Battery production has to be a clean business. The new SEEPEX BF range pumps are certainly clean and offer an important advantage in several respects. "Operational safety and maximum cleanliness when using valuable dispersed raw materials were the driving forces behind the development of the BF range. It helps reduce total cost of ownership and improve energy efficiency in virtually all battery applications by eliminating contamination and being easy to maintain. Cleaning cycle failures and disposal of contaminated battery compounds are not only wasteful, but also very costly," says Dufner. "Chemical resistance and chemically compatible materials are necessary to prevent contamination of expensive raw materials. With BF, we assure that the materials are chemically compatible. The stainless steel design and flexible titanium shaft ensure contamination-free product quality. Contamination by oil or grease is impossible. The pumps can be thoroughly cleaned with common solvents and deionized water."

Maximum dosing accuracy with minimal pulsation

Battery compounds, from lithium to electrolyte, can be added to the mixing process in precise, drop-by-drop doses. Continuity and high repeatability are critical during the formulation process. In the coating process, the pump has a direct impact on product quality by minimizing variations in coating thickness. The BF range achieves this continuity and high repeatability by using the SEEPEX progressive cavity pump principle with the advantage of extremely low pulsation. This ensures the highest dosing accuracy, resulting in better coating results and more accurate slurry recipes.

Leaking is a shortcoming in many pump types. Failures due to leakage or stick-slip are known to cause health and environmental hazards. SEEPEX progressive cavity pumps, with their special design, have no spillage or leakage due to their high degree of sealability. In addition, a wide range of seals is available for different battery compounds. SEEPEX keeps it tight, so the voltage stays in the electrical future.

Well-equipped to meet growing demands

The fast-growing lithium-ion battery industry requires a large number of cost-effective pumps. Especially in China, availability and delivery reliability for large volumes are important. According to industry sources, the world market leader plans to launch batteries with a volume of almost 900 gigawatt hours this year. SEEPEX is well prepared: The German engineering company produces its battery pumps locally in Shanghai and Bottrop, Germany, in order to be able to offer large quantities with short delivery times.