www.ptreview.co.uk

11

'23

Written on Modified on

DESKTOP METAL LAUNCHES THE ETEC PRO XL INDUSTRIAL POLYMER 3D PRINTER

ETEC Pro XL can process a wide range of industrial, jewellery casting, and health photopolymers — including specified resins from trusted third-party providers, such as Henkel Loctite®, Evonik, and BASF.

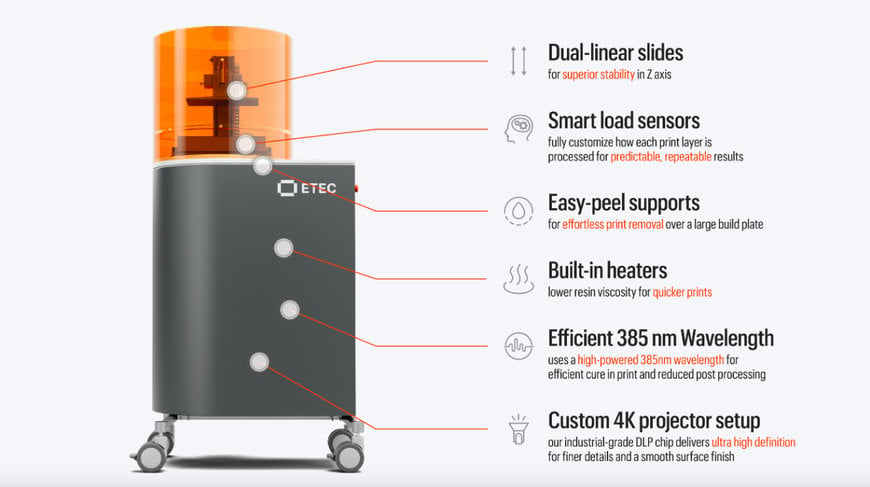

Now available below $40,000, the ETEC Pro XL premium polymer 3D printer delivers extreme accuracy, resolution, and surface finish in a large build area with the high throughput speeds for which area-wide DLP technology is known. (Photo: Business Wire)

Desktop Metal announced the launch of the ETEC Pro XL — a premium polymer DLP printer that enters the market at less than half the price as its predecessor.

The ETEC Pro XL features a large build area of 249.1 x 140.1 x 165.1 mm (9.8 x 5.5 x 6.5 in) and a significant number of new, high-value updates:

Desktop Metal announced the launch of the ETEC Pro XL — a premium polymer DLP printer that enters the market at less than half the price as its predecessor.

The ETEC Pro XL features a large build area of 249.1 x 140.1 x 165.1 mm (9.8 x 5.5 x 6.5 in) and a significant number of new, high-value updates:

- a 4K ultra-high-definition projector (3840 x 2160 pixels) delivers optimum build size and pixel resolution

- a premium 385 nm wavelength light engine delivers 5mW/cm^2 power density that translates into faster layer exposure times

- HyperPrint™ technology turbocharges already-fast DLP print times with a resin heater and closed-loop sensing system for continuous isotropic printing with low pulling forces

- native XY resolution of 65 μm with dynamic voxel resolution in Z, material dependent, of 25, 50, or 100 μm

The ETEC Pro XL is currently qualified for use with E-Rigid Form Charcoal, a polyurethane-like resin with high strength and stiffness; HTM 140, a high-temperature moulding material; and Easy Cast 2.0, a high-wax jewellery casting material. ETEC Pro XL is also backwards-compatible with materials previously approved for prior models of the P4K and Perfactory upon request. This system is also compatible with third-party resins from trusted manufacturers such as Henkel Loctite (IND3843 and IND405™), Evonik (INFINAM ST 6100), and BASF (Ultracur3D® RG 3280).

The approved rigid, high-heat, and castable materials available on this system make it ideal for use with a variety of industrial, jewellery, and medical applications such as automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, microfluidic devices, castable jewellery patterns, short-run moulds, fluid ducts, and prosthetics.

Benefits of DLP Printing

ETEC Pro XL is a DLP printing system, a form of 3D printing photopolymers that originated in 2002 with the EnvisionTEC Perfactory, the base platform of the ETEC Pro XL.

DLP delivers both high speed and quality by harnessing the power of a high-definition projector to rapidly flash and cure one layer of resin at a time using a theatre-quality DLP chip. Because projectors expose light in pixels, the brightness of each pixel can be controlled individually. That allows for the curing of each pixel to different depths or volumetric pixels, also known as voxels. The ability to control each voxel dramatically improves the accuracy and surface quality of 3D printed parts, especially when paired with custom optics and specific light wavelengths.

The ETEC Pro XL features a 4K UHD projector powered by an industrial DLP chip below the print vat. Dual linear slides for the moving build plate ensure a high-accuracy print across the entire print bed by maintaining a parallel build environment. Depending on the material being processed, layer thicknesses down to 25 microns can be achieved. Custom optics and a premium 385 wavelength for superior curing, are just some of the upgrades offered in this new system.

Learn more about the ETEC Pro XL here.

The approved rigid, high-heat, and castable materials available on this system make it ideal for use with a variety of industrial, jewellery, and medical applications such as automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, microfluidic devices, castable jewellery patterns, short-run moulds, fluid ducts, and prosthetics.

Benefits of DLP Printing

ETEC Pro XL is a DLP printing system, a form of 3D printing photopolymers that originated in 2002 with the EnvisionTEC Perfactory, the base platform of the ETEC Pro XL.

DLP delivers both high speed and quality by harnessing the power of a high-definition projector to rapidly flash and cure one layer of resin at a time using a theatre-quality DLP chip. Because projectors expose light in pixels, the brightness of each pixel can be controlled individually. That allows for the curing of each pixel to different depths or volumetric pixels, also known as voxels. The ability to control each voxel dramatically improves the accuracy and surface quality of 3D printed parts, especially when paired with custom optics and specific light wavelengths.

The ETEC Pro XL features a 4K UHD projector powered by an industrial DLP chip below the print vat. Dual linear slides for the moving build plate ensure a high-accuracy print across the entire print bed by maintaining a parallel build environment. Depending on the material being processed, layer thicknesses down to 25 microns can be achieved. Custom optics and a premium 385 wavelength for superior curing, are just some of the upgrades offered in this new system.

Learn more about the ETEC Pro XL here.