www.ptreview.co.uk

14

'25

Written on Modified on

ABB Launches Motor Connector to Cut Costs and CO₂ Emissions

ABB’s Motor Connector portal helps users boost motor efficiency, reduce energy costs, and calculate CO₂ savings with powerful digital tools.

global.abb

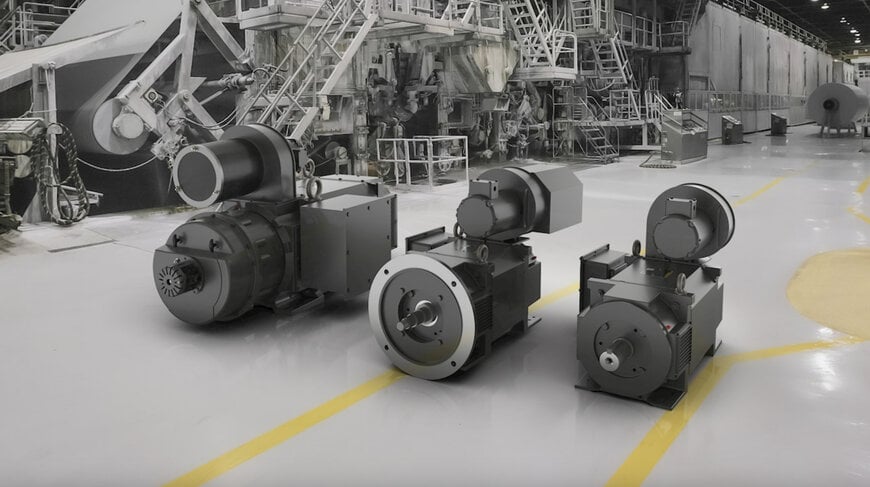

Forty-five percent of the world’s electricity is used to power electric motors in buildings and industrial applications.1 By 2030, this cost is projected to reach $900 billion annually.2 Lowering CO₂ emissions and increasing energy efficiency is critical for our planet, but also for ensuring stable and productive industry operations, lowering operating costs and total cost of ownership. To help motor operators better understand the financial and environmental benefits of upgrading current and end-of-life industrial electric motors, ABB has introduced Motor Connector, an online portal to help users quickly and easily locate and navigate ABB’s portfolio of feature-rich customer applications.

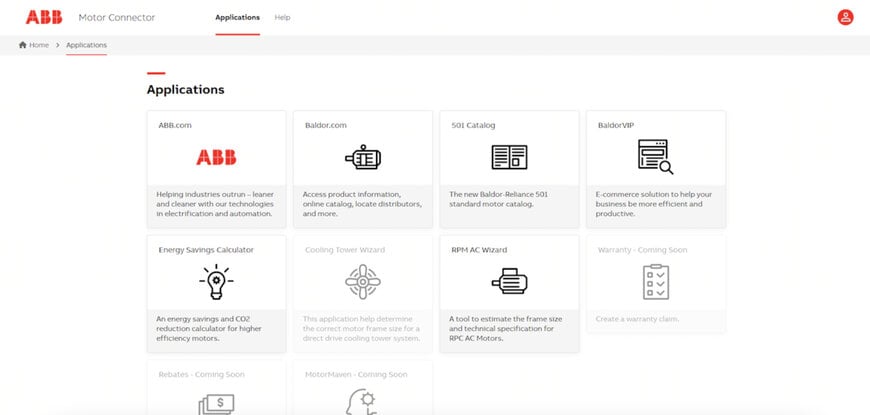

The ABB Motor Connector is a dedicated, user-friendly platform designed to enhance customer experience by providing customers with a centralized hub for accessing essential applications and information. Customers can effortlessly manage their accounts, request and access applications all within a secure and intuitive interface. This portal integrates with various backend systems to ensure real-time updates and seamless communication, allowing NEMA Motors to offer personalized, efficient, and responsive service. This resource streamlines business operations, making it easier for ABB to manage customer interactions and address their needs promptly. Motor Connector provides quick and easy access to several applications:

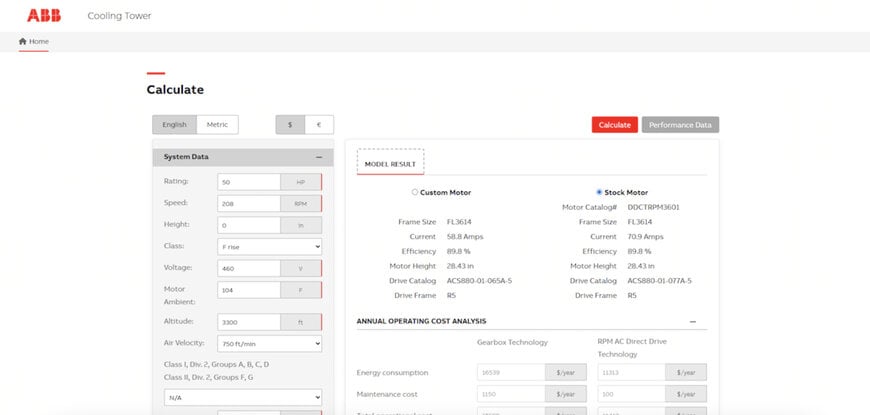

Cooling Tower Wizard is a web tool designed to help users select the most suitable ABB Baldor-Reliance cooling tower direct drive motor for their specific needs. The application allows users to compare different models and configurations based on various criteria such as energy efficiency, cost of operation and footprint, provides energy savings calculation, a performance data packet and downloadable data reports.

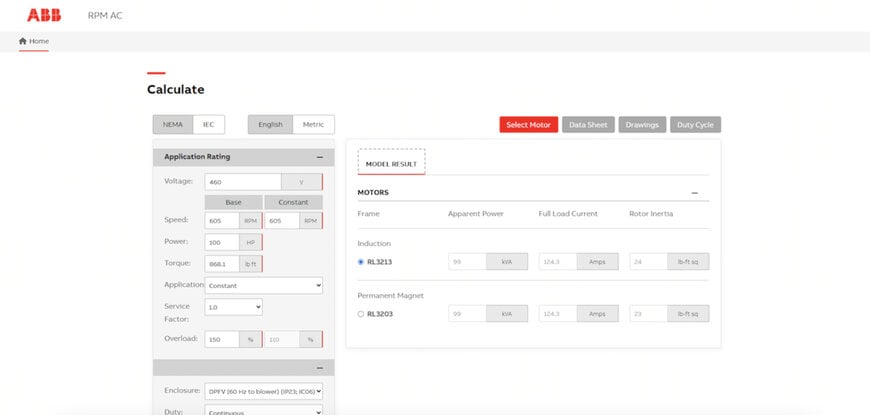

RPM AC Wizard is a web tool designed to help users select the most suitable Baldor-Reliance RPM AC motor for their specific needs. The application allows users to compare different models and configurations based on various criteria such as energy efficiency, cost of operation, and footprint. RPM AC Wizard outputs energy savings calculation, performance data, duty cycle information, and CAD drawings.

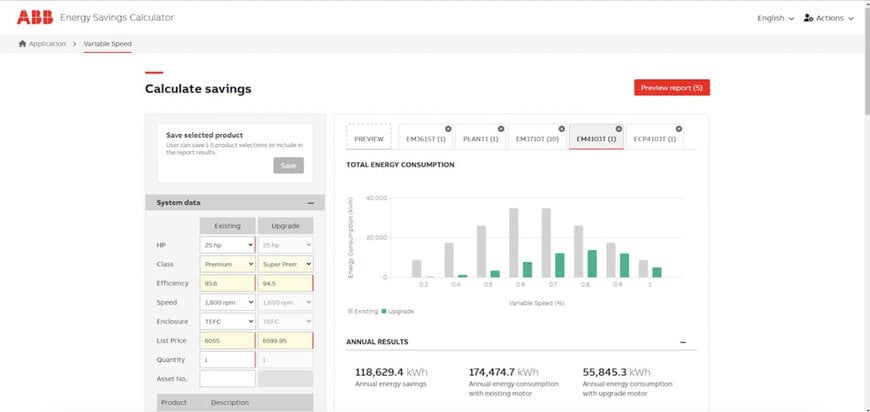

The Energy Savings Calculator is an online tool that allows users to compare the electrical energy usage, costs and CO2 reduction of a motor currently in operation with that of a new, highly efficient Baldor-Reliance SP4™ NEMA Super Premium® efficiency motor. The tool has two modes: basic and advanced. The basic function allows users to search existing ABB Baldor-Reliance motors by catalog number, while the advanced option has fields for motor parameters such as power, efficiency class, speed and enclosure type to allow for comparisons with any existing motor. Annual savings in kilowatt hours, energy percentages and U.S. dollars are provided, as well as energy consumption comparisons between the new and existing motor and annual CO2 reduction. A digital report with data and graphics can be exported in both the basic and advanced functions. Recent updates to the Energy Savings Calculator have added variable speed motor calculations, input capabilities for multiple motors and additional enhancements.

It has been estimated that, if more than 300 million industrial electric motor-driven systems currently in operation were replaced with optimized, high-efficiency equipment, global electricity consumption could be reduced by as much as 10 percent.3 The benefits of greater energy efficiency go well beyond the fight against climate change. They contribute broadly to environmental conservation, cleaner air and water, better public health, energy independence, stronger economic growth and development.

As the cost of electricity continues to rise – along with the demand for electricity driven by population growth and new technologies – ABB will remain at the forefront of energy efficiency and sustainability by embedding circularity in products and solutions, offering lifetime services and investing in new business models and technologies to reduce waste, increase recycling and foster reusability.

1] ABB, 2021. Achieving the Paris Agreement – The vital role of high-efficiency motors and drives in reducing energy consumption

2] ETC, 2021. Making Clean Electrification Possible: 30 Years to Electrify the Global Economy

3] Waide, P. and C.U. Brunner, 2011. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems, International Energy Agency working paper

www.abb.com