www.ptreview.co.uk

16

'25

Written on Modified on

TDK launches SensEI's edgeRX Vision AI

TDK SensEI's edgeRX Vision is an ultra-fast, AI-powered defect detection system, precisely identifying 1mm components, operating at 2,000 parts per minute.

www.tdk.com

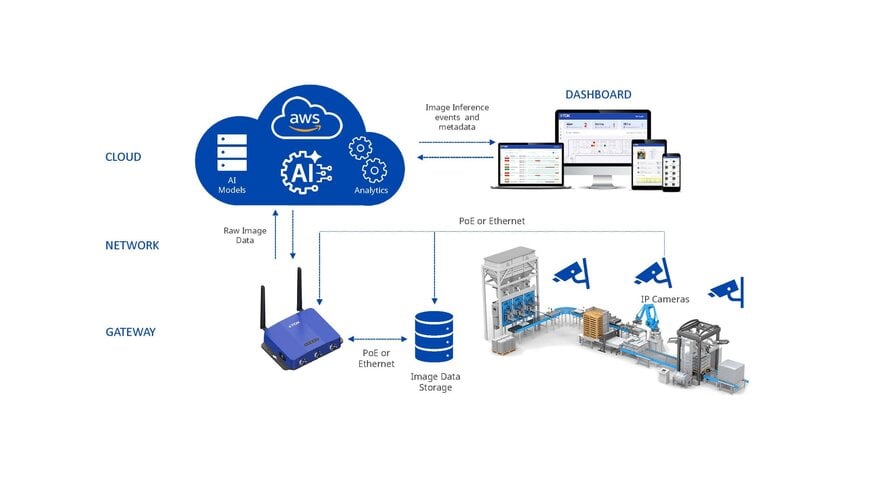

edgeRX Vision is a high-speed defect detection system that analyzes customer product images or movies and is capable of identifying even the smallest components—down to 1 mm by 0.5 mm—with exceptional precision. Powered by advanced AI, the system delivers real-time, highly accurate defect detection while significantly reducing false positives. Working in conjunction with TDK SensEI’s edgeRX platform and sensors, edgeRX Vision enhances existing hardware infrastructure to minimize unnecessary machine stoppages and ensure a smoother, more efficient production flow. Operating at speeds of up to 2,000 parts per minute, even slight reductions in downtime can lead to substantial revenue gains—making edgeRX Vision an essential solution for high-throughput manufacturing environments.

Key features of edgeRX Vision include:

- High-precision product defect detection

- Adaptive learning and continuous improvement

- Reduced false positives and negatives

- Scalability across product lines

AI-based machine vision has evolved into a highly advanced and reliable technology, widely adopted across industries for its speed, precision, and adaptability. Modern systems leverage edge AI to process visual data in real time, reducing latency and dependence on cloud infrastructure. Transformer-based architectures and unified models like DINOv2 and SAM enable a wide range of vision tasks—such as detection, segmentation, and classification—without the need for task-specific retraining. These systems are also becoming more label-efficient through self-supervised and few-shot learning, lowering the cost of data preparation. Integration with language models has introduced multi-modal capabilities, allowing for more intuitive human-machine interaction. With these enhancements and new capabilities transforming the industry, now is a pivotal moment for TDK SensEI to introduce edgeRX Vision to the marketplace. AI-driven vision systems have become more scalable, robust, and cost-effective than ever before, making them essential for high-throughput, real-world production environments.

“edgeRX Vision will further enhance our existing automatic optical inspection (AOI) capabilities with high-velocity, AI-powered defect detection—right at the edge,” said Ken Takekawa, CEO of TDK Components USA. It’s capable of handling even the smallest MLCCs, measuring down to 1 mm by 0.5 mm, with exceptional precision. By deploying AI on our existing hardware, we significantly reduced the total cost of ownership by minimizing false positives. This improvement will lead to fewer machine stoppages due to inspection overkill and result in much higher production throughput. At speeds of up to 2,000 parts per minute, even small-time savings translate into substantial revenue gains.”

Glossary

“edgeRX Vision will further enhance our existing automatic optical inspection (AOI) capabilities with high-velocity, AI-powered defect detection—right at the edge,” said Ken Takekawa, CEO of TDK Components USA. It’s capable of handling even the smallest MLCCs, measuring down to 1 mm by 0.5 mm, with exceptional precision. By deploying AI on our existing hardware, we significantly reduced the total cost of ownership by minimizing false positives. This improvement will lead to fewer machine stoppages due to inspection overkill and result in much higher production throughput. At speeds of up to 2,000 parts per minute, even small-time savings translate into substantial revenue gains.”

Glossary

- Edge AI: The deployment of artificial intelligence models directly on local hardware (edge devices), allowing real-time data processing without needing to send data to the cloud

- Transformer-Based Architectures: A class of deep learning models (e.g., Vision Transformers or ViTs) that process visual data using attention mechanisms, offering improved performance over traditional convolutional neural networks (CNNs)

- Unified Vision Models: AI models like DINOv2 and Segment Anything Model (SAM) that can perform multiple vision tasks (e.g., detection, segmentation, classification) without needing separate models for each task

- Few-Shot Learning: The ability of a model to learn new tasks or recognize new patterns from a very small number of examples

- Multi-Modal AI: Systems that combine different types of data—such as images and text—to perform tasks like visual question answering or image captioning. Examples include models like CLIP and BLIP-2

- False Positives/Negatives: In defect detection, a false positive is when a good part is incorrectly flagged as defective, while a false negative is when a defective part is missed

- AOI: Automatic Optical Inspection

Main applications

- Electronics manufacturing

- Pharmaceuticals

- Food and beverage

Main features and benefits

- Improved Product Quality: ensuring consistent detection of defects, leading to higher-quality output

- Reduced False Positives: Minimizes unnecessary rejections, keeping production lines running smoothly

- Increased Throughput: Enables faster inspection without compromising accuracy, boosting production efficiency

- Lower Operational Costs: Reduces labor costs and waste by automating inspection and minimizing rework