www.ptreview.co.uk

30

'25

Written on Modified on

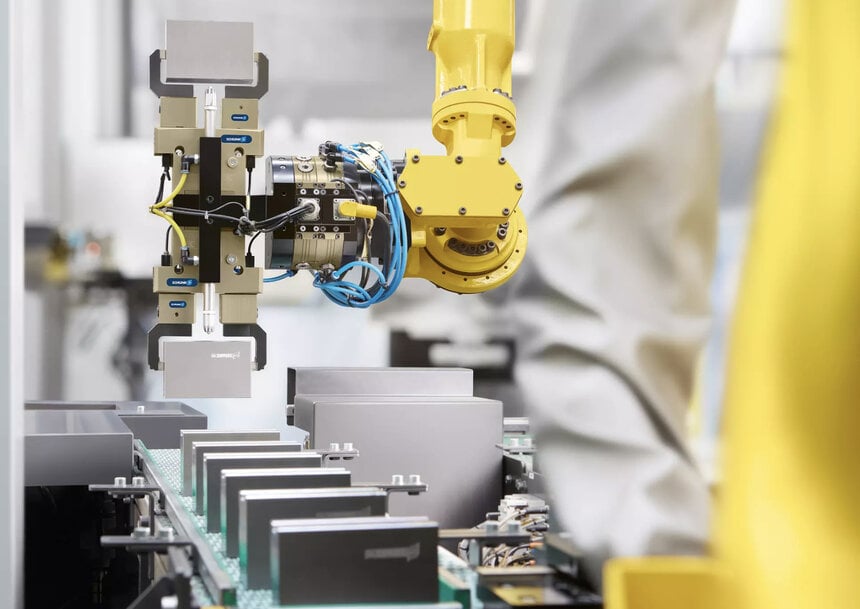

New Robot PLUS by SCHUNK offers versatile options for flexible robotic automation

SCHUNK combines tool changers, compensation units, sensors, and grippers into flexible end-of-arm solutions, enabling fast, reliable tool exchange for handling weights up to 1,000 kg.

schunk.com

Flexibility is key for modern automation – and SCHUNK provides the right solutions. The technology pioneer is expanding its future-proof end-of arm portfolio for robot applications made by SCHUNK in Germany. The portfolio covers the area between the robot flange and the end effectors and can be flexibly adapted to individual requirements. In doing so, the company is setting the course for the future, while building on decades of experience in automation technology.

Tool changers: mastering component variety efficiently

With a tool changer, robots are able to perform a variety of handling or machining tasks flexibly and without additional set-up time. They allow grippers, tools, and other end effectors to be exchanged quickly and easily. This minimizes downtime. The Robot PLUS portfolio currently includes three different products in this category.

For industrial applications, both CPS and CPB tool changers are ideally suited. They exchange end effectors fully automatic via pneumatics. Moreover, they allow various media transfers through a wide range of signal, pneumatic, fluid, and communication modules.

The CPS tool changer is a flexible all-rounder, where the change master (CPS-K) and the adapter (CPS-A) are connected form-fit and process-reliably via a ball-seated locking mechanism. The system enables a rapid and process-reliable exchange of grippers and other tools with a handling weight of up to 1,000 kg. Since all functional parts are made of hardened steel, the CPS is suitable for use in harsh industrial environments. The series comprises 18 sizes, offering the matching changer for any robot. When replacing existing SCHUNK changers, users do not need to re-teach, as the CPS is fully compatible.

The CPB tool changer ensures efficient tool changes, providing maximum flexibility and process-reliability. The special feature of the CPB is its robust locking mechanism with pins. SCHUNK has leveraged over 20 years of development experience in stationary workholding, bringing the proven system from the machine table to the robot. The form-fit, self-retaining pin mechanism made of vacuum-hardened stainless steel offers maximum stability and long service life. The integrated ISO interface allows for fast assembly and reduces the commissioning effort.

The manual CMS change system is the ideal addition to various tasks in manufacturing, handling technology, or at assembly workstations. This compact and user-friendly system allows for quick changes at the robot‘s front end. Thanks to the proven push-lever technology, the CMS can be easily locked and unlocked with minimum effort and without the need of any additional tools. It handles payloads up to 58 kg. The integrated monitoring sensor system also ensures operational and process reliability. Thanks to the ISO flange pattern, the CMS can be mounted to any standard robot type without an additional adapter plate.

The AGM compensation unit effectively compensates tolerances in automated processes with robots. This helps prevent, for example, jamming situations when loading and unloading machine tools, inaccuracies in joining processes, or sticking during bin picking. The modular AGM product range comprises 23 sizes, so there is no need to compromise on interfering contours. With a wide range of variants available, users will always find the right unit for every application. The AGM also scores highly when it comes to compensation behavior: it can compensate for movements in all directions, (XY, Z, W) and their combinations (XYZ, WZ). Particularly impressive is the high payload capacity, which spans from just a few grams to over 400 kg. The patented spring and air cartridges ensure reliable weight compensation – even in horizontal or inclined positions – while the sturdy and robust guides ensure a long serve life.

Whether for quality control - for example in the battery manufacturing for e-Mobility - process monitoring, or grinding and assembly tasks: the FTS 6-axis force/torque sensor captures process forces and moments with high resolution and precision. This enables reliable evaluation of all acting forces. Continuous monitoring ensures consistently high manufacturing quality and precise results. Equipped with IP67 protection class, the FTS sensor is available in nine sizes and delivers dependable performance even under challenging conditions. The interface box with support for EtherNet/IP, EtherCAT, and PROFINET ensures easy integration into existing systems.

With the Robot PLUS portfolio, SCHUNK creates versatile options for flexible robotic automation. Thanks to decades of expertise in developing tailored, well-engineered automation components, SCHUNK stands for exceptional productivity, flexibility, and resource efficiency.

www.schunk.com