www.ptreview.co.uk

05

'25

Written on Modified on

Efficient and simple automation with KUKA robots

KUKA's automation solutions for industrial welding applications will be on display in action at the international trade fair SCHWEISSEN & SCHNEIDEN in Essen.

www.kuka.com

Under the motto "Get complex paths on track. But easier.“ KUKA's automation solutions for industrial welding applications will be on display in action at the international trade fair SCHWEISSEN & SCHNEIDEN in Essen from September 15 to 19. In Hall 3, Stand D48, visitors can get to know robots in a wide range of payload classes and find out about intuitive software packages and control technology on site.

Smart software for simple welding automation

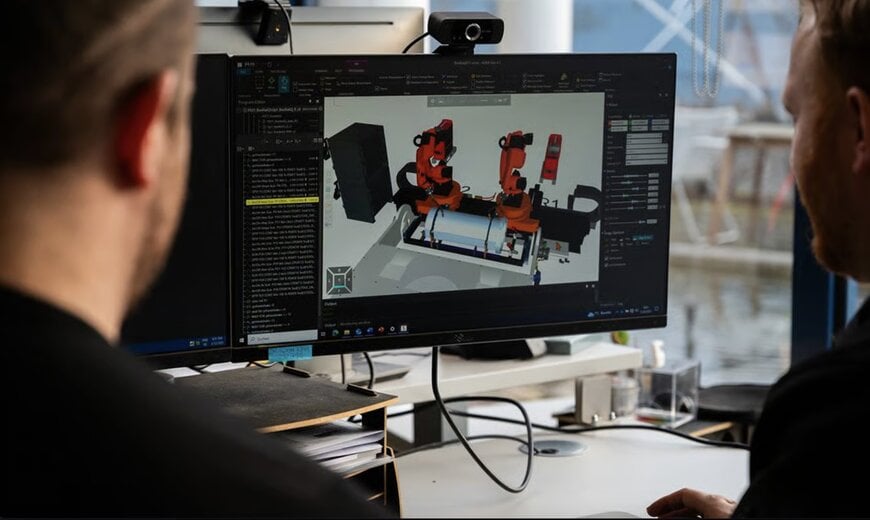

At the trade fair, KUKA will demonstrate how it is consistently expanding its software portfolio based on the new iiQKA.OS2 robot operating system, while also addressing the simple and efficient automation of welding applications. The new iiQKA.OS2 operating system is scalable, AI-enabled, and cyber-resilient. It opens up completely new possibilities right from the planning stage. The simulation of robots and their peripherals is made possible by iiQKA.OS2 in combination with the all-in-one engineering suite iiQWorks and the digital twin.

KUKA will also be showcasing the "Path Planning Feature" at the trade fair, which will be available from October and will further simplify the planning of automation projects specifically for welding and cutting applications in iiQWorks. The software offering is rounded off by smart operating devices such as the SmartPAD pro and the SmartPLUG, which enable intuitive control and rapid integration of the robots – in line with the principle of "making automation easier."

Get complex paths on track. But easier.

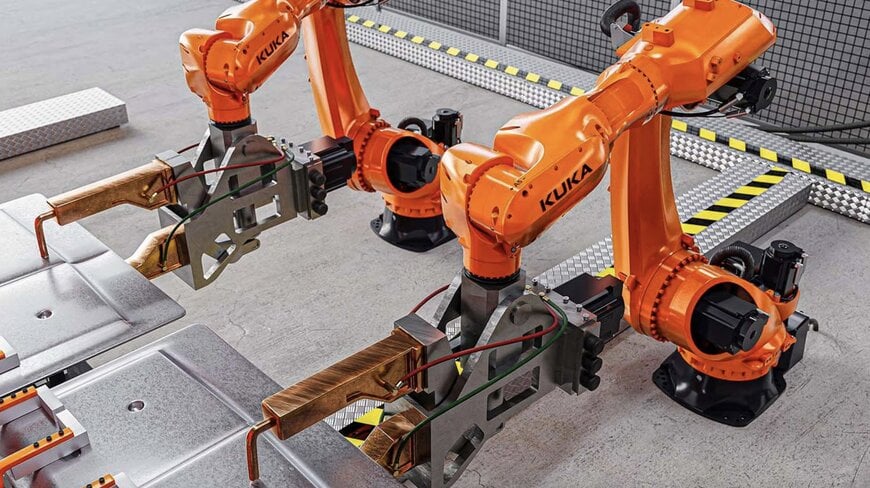

In the hardware sector, KUKA is showcasing the KR IONTEC ultra as a trade fair highlight. Available in the portfolio since 2025, this robot is ideal for spot welding with light-weight welding guns. Thanks to its compact design, it fits perfectly into narrow welding cells and impresses with a payload of up to 120 kg, high dynamics, and minimal maintenance requirements, making it highly sought after by automotive suppliers.

In addition to the KR IONTEC ultra, KUKA will be demonstrating at Schweißen und Schneiden 2025 that robot cells offer highly automated solutions for friction stir welding in electric vehicle production with the new KR FORTEC ultra MT. Thanks to its high rigidity, the heavy-duty robot delivers very precise weld seams that require no reworking – in line with KUKA's trade fair motto "Get complex paths on track. But easier."

Latest developments in friction welding technology

Welding machines from KUKA and Thompson make industrial joining of a wide variety of materials easy and cost-effective. This also enables the welding of demanding and safety-relevant material combinations for industries such as e-mobility and lightweight construction with the highest quality. At the KUKA booth at Schweißen & Schneiden, visitors can learn about the advantages of friction and MagnetArc welding machines and discover new technologies such as linear friction welding, hybrid rotary friction welding, and stir friction welding with steel.

www.kuka.com