www.ptreview.co.uk

15

'25

Written on Modified on

Mitutoyo Introduces QM-Fit: A Smart Vision System for Fast, Intuitive Measurement

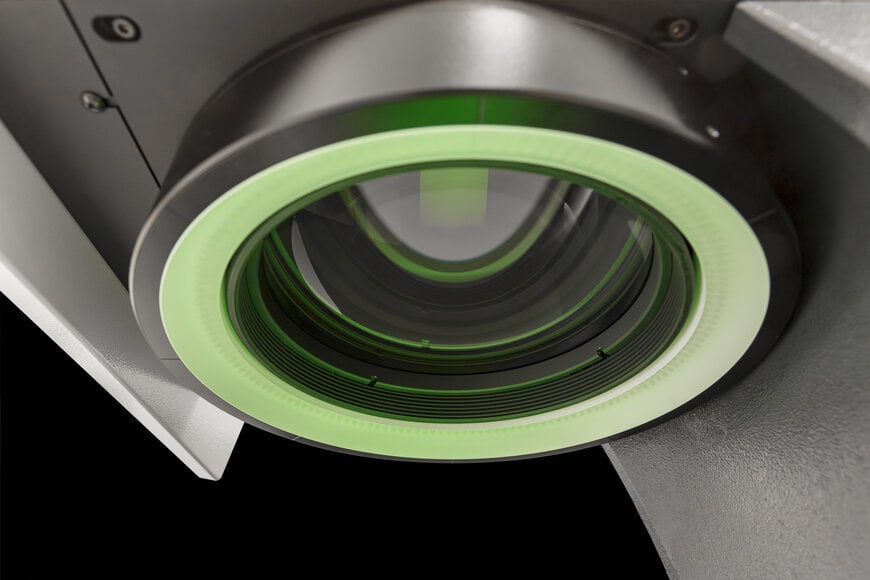

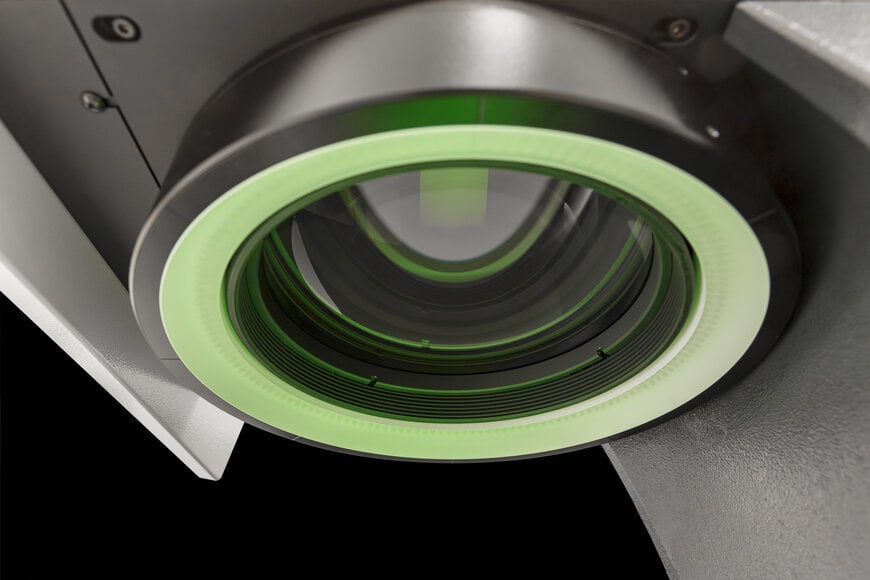

QM-Fit is a compact, stand-alone unit with an integrated PC, 15.6-inch touch monitor, and a 20MP CMOS camera offering 100x digital zoom, telecentric lens, and 36 mm depth of field for high-resolution imaging and precise focus on uneven parts.

www.mitutoyo.eu

Mitutoyo, global leader in precision measurement solutions, is proud to announce the launch of QM-Fit, a compact, high-performance manual vision measuring machine designed for quick, accurate inspection of small and thin components. QM-Fit redefines ease of use with a smart, touch-based interface and is positioned as a next-generation alternative to traditional profile projectors.

A Smarter Way to Measure

QM-Fit is built to make precision measurement accessible to everyone—regardless of skill level. With its intuitive User Interface, touch panel operation, and advanced automatic part recognition, users can simply place a part on the stage and initiate measurement instantly. The system automatically detects features such as circles and edges, and offers real-time, graphical feedback.

Key Advantages & Efficiency Highlights

Instant Measurement with Automatic Recognition

QM-Fit offers instant measurement with automatic recognition, allowing users to simply place the part on the stage. The system immediately identifies the workpiece, detects circles, lines, and other elements without the need for setup, alignment, or manual focusing, and begins measurement right away.

Intuitive Operation—No Skills Required

Its intuitive touchscreen interface ensures that no special skills are required to operate the system. Visual guides and auto-suggestions minimize training time and reduce user errors, while results are displayed graphically in real time with clear pass/fail indicators.

Graphically Supported Caliper Snap

Another standout feature is the Graphically Supported Caliper Snap, which enables fast and precise measurement by snapping digital rulers to part edges or geometries—eliminating the time-consuming crosshair alignment used in traditional projectors.

Higher Throughput, Lower Costs

QM-Fit also improves productivity and reduces costs by delivering repeatable results with minimal operator influence, cutting down on variation and rework. Automatic detection and digital zoom shorten cycle times, helping to remove bottlenecks in quality control and first-article inspection processes.

Compact, Space-Saving Design, Powerful Optics & High-Resolution Imaging

With its compact, space-saving design (366 × 407 × 621 mm and 25 kg), QM-Fit fits easily on any workbench and operates as a true stand-alone unit, complete with integrated PC and 15.6-inch touch monitor. Its powerful 20MP CMOS color camera, digital zoom up to 100x, telecentric lens, and 36 mm depth of field provide high-resolution imaging and accurate focus even on uneven parts.

Reliable and Traceable

Finally, the system ensures reliability and traceability, with calibration to ±10 µm accuracy and repeatability within 2σ ≤ 4 µm. Built-in traceability functions and environmental correction further enhance measurement confidence.

A Better Alternative to Profile Projectors

While traditional projectors require manual alignment and operator skill, QM-Fit automates these steps with smart detection and digital visualization. It delivers faster, more consistent results, making it an ideal replacement for optical comparators in quality control, incoming inspection, and shop floor applications.

www.mitutoyo.eu

A Smarter Way to Measure

QM-Fit is built to make precision measurement accessible to everyone—regardless of skill level. With its intuitive User Interface, touch panel operation, and advanced automatic part recognition, users can simply place a part on the stage and initiate measurement instantly. The system automatically detects features such as circles and edges, and offers real-time, graphical feedback.

Key Advantages & Efficiency Highlights

Instant Measurement with Automatic Recognition

QM-Fit offers instant measurement with automatic recognition, allowing users to simply place the part on the stage. The system immediately identifies the workpiece, detects circles, lines, and other elements without the need for setup, alignment, or manual focusing, and begins measurement right away.

Intuitive Operation—No Skills Required

Its intuitive touchscreen interface ensures that no special skills are required to operate the system. Visual guides and auto-suggestions minimize training time and reduce user errors, while results are displayed graphically in real time with clear pass/fail indicators.

Graphically Supported Caliper Snap

Another standout feature is the Graphically Supported Caliper Snap, which enables fast and precise measurement by snapping digital rulers to part edges or geometries—eliminating the time-consuming crosshair alignment used in traditional projectors.

Higher Throughput, Lower Costs

QM-Fit also improves productivity and reduces costs by delivering repeatable results with minimal operator influence, cutting down on variation and rework. Automatic detection and digital zoom shorten cycle times, helping to remove bottlenecks in quality control and first-article inspection processes.

Compact, Space-Saving Design, Powerful Optics & High-Resolution Imaging

With its compact, space-saving design (366 × 407 × 621 mm and 25 kg), QM-Fit fits easily on any workbench and operates as a true stand-alone unit, complete with integrated PC and 15.6-inch touch monitor. Its powerful 20MP CMOS color camera, digital zoom up to 100x, telecentric lens, and 36 mm depth of field provide high-resolution imaging and accurate focus even on uneven parts.

Reliable and Traceable

Finally, the system ensures reliability and traceability, with calibration to ±10 µm accuracy and repeatability within 2σ ≤ 4 µm. Built-in traceability functions and environmental correction further enhance measurement confidence.

A Better Alternative to Profile Projectors

While traditional projectors require manual alignment and operator skill, QM-Fit automates these steps with smart detection and digital visualization. It delivers faster, more consistent results, making it an ideal replacement for optical comparators in quality control, incoming inspection, and shop floor applications.

www.mitutoyo.eu