www.ptreview.co.uk

17

'25

Written on Modified on

New functions of the TNC7 and introducing the TNC7 go

More manufacturing possibilities: With expanded functionality and a broader TNC7 portfolio, HEIDENHAIN offers machine manufacturers and users new application areas and innovative machining technologies.

www.heidenhain.com

More possibilities for manufacturing: By expanding the range of functions and the product portfolio of the TNC7 controls, HEIDENHAIN opens up new areas of application and machining technologies for machine manufacturers and users:

- Cylindrical grinding and shaping, as well as new options for cylinder surface machining, expand the scope of functions of the TNC7 for done-in-one machining. Visitors to the trade show can experience the new possibilities during live demonstrations on the machine tool at the HEIDENHAIN booth.

- The simulation functions have been enhanced further so that NC programs can be checked in detail even more conveniently before execution and to ensure that they run reliably on the machines.

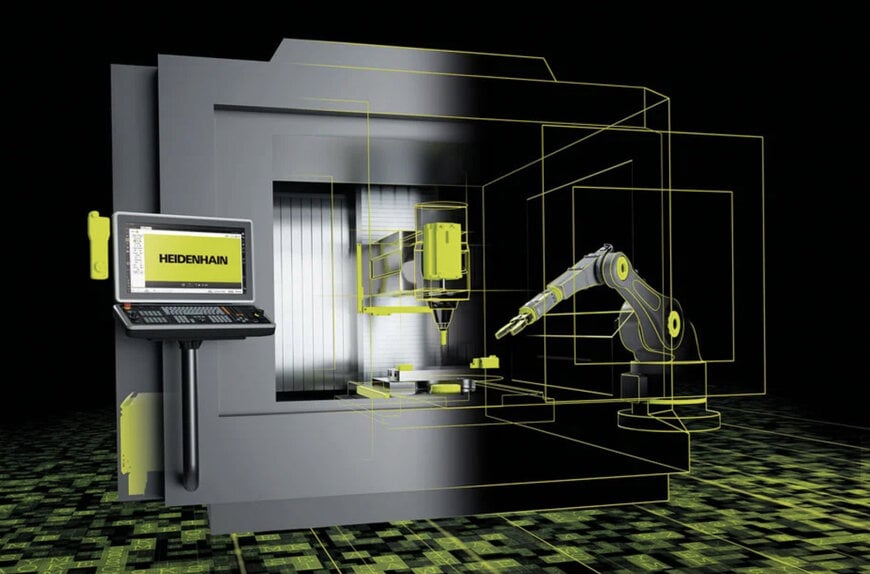

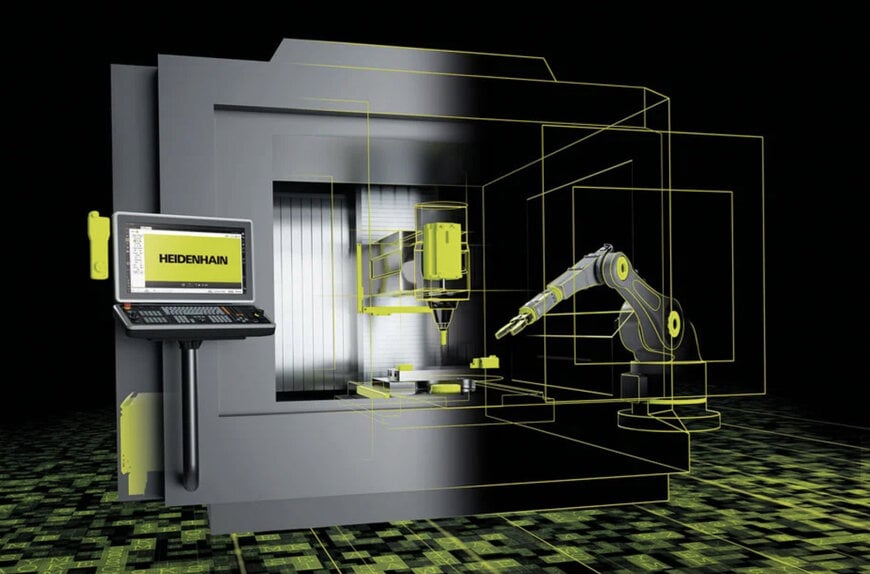

- HEIDENHAIN is teaching robots how to understand Klartext. This makes it possible to use a TNC control to directly manage a robot in an automated machine tool.

- With the TNC7 go, the intuitive and pioneering operating design of the TNC7 family is tailored to vocational training and machine upgrades.

For done-in-one machining and production of workpieces with the highest dimensional, geometrical, and surface accuracy, the TNC7 controls now offer shaping and cylindrical grinding technologies. TNC7 users will have milling, turning, and grinding capabilities at their fingertips, all without needing to rechuck the workpieces.

The shaping function makes it possible to manufacture sealing surfaces with high surface quality. This is needed, for example, in battery manufacturing and the semiconductor industry. The control automatically keeps the shaping tool at right angles to the contour, so the user does not need to program the spindle angle. The control automatically takes a tilted working plane and any cutter offset into account. With the right tools, users can also use shaping to chamfer edges up to special surface quality specs (beveling) or to engrave patterns into surfaces (engine turning) as is needed for printing technology or the jewelry and watchmaking industry.

At this year's EMO, HEIDENHAIN will present the cylindrical grinding functions for the TNC7 control for the first time. They further increase the potential of machining centers for done-in-one machining with milling, turning, and grinding on a single machine. Standardized cycles are available for cylindrical grinding as well as for the dressing of grinding wheels. The cycles support both the long-stroke and short-stroke grinding of rotationally symmetrical workpieces. In the process, reciprocating and infeed movements are performed independently of each other, thus making it possible to already optimize the machining process while proving-out, without needing to change the NC program. The cycles also automatically consider the machine kinematics regarding approach and departure movements, thereby helping users to deal with complex machines and challenging approach conditions.

The TNC7 and TNC7 basic also offer new cylinder surface machining capabilities. The cylinder surface transformation functionality now makes it possible to apply the already very comprehensive cycles for cylinder surface machining of nearly all milling, drilling, and engraving processes to a cylinder surface. To achieve this, the tool must be oriented perpendicularly to the rotary table axis and the cylindrical workpiece. When this transformation functionality has been activated, the user simply programs the required cycles and movements on the cylinder surface. During machining, the motion of the rotary table keeps the tool perpendicular to the cylinder surface.

Starting at EMO 2025, two new functions will complement the extensive simulation capabilities of the TNC7 controls and facilitate the verification of NC programs based on machine simulation. And by fast-forwarding and rewinding the tool path in the simulation, including the entire machine kinematics in the simulated TCP path, users can examine critical traverse movements in detail. The simulation report shows detected warnings and errors in a clear format, thus facilitating efficient and effective error analysis. Users can decide whether messages from the simulation are shown in the message menu of the information bar (as in the past) or in the Simulation report column in the Program workspace.

HEIDENHAIN is making the operation of handling robots on automated machine tools easier with a new solution: Users operate and program the robot directly via the TNC, without requiring any separate knowledge of robot control. This is possible because the movements of both the machine tool and the robot are programmed identically through the control's user interface. The robot is programmed via Klartext cycles, which is done very easily using the integrated teach-in processes. Users can incorporate various robot functions, such as pick-and-place, deburring, or gripper control, as desired. The robot control is connected to the TNC via Ethernet and does not require bus systems, meaning that this retrofitting is also very easy for legacy machines.

With the TNC7 go, HEIDENHAIN tailors the pioneering and intuitive user experience of the TNC7 family to vocational training applications and older machines, expanding on the practical functions that greatly simplify daily work. This particularly includes the new “graphical positioning” function. Instead of writing an NC program, the user draws the desired contours, patterns, or drilling positions directly on the touchscreen. The control then automatically handles their execution. Equally helpful are the new “Manual Cycles,” which enable typical machining tasks such as drilling or face milling without programming. With these features, the TNC7 go is just as ideal for anybody new to machine tools as it is for experienced professionals looking for fast results. The TNC7 go stands for efficient productivity, a short learning curve, and a user-friendly CNC experience. It is perfectly designed for the needs of state-of-the-art vocational training centers, shop floors, and machine upgrade projects.

www.heidenhain.com

The shaping function makes it possible to manufacture sealing surfaces with high surface quality. This is needed, for example, in battery manufacturing and the semiconductor industry. The control automatically keeps the shaping tool at right angles to the contour, so the user does not need to program the spindle angle. The control automatically takes a tilted working plane and any cutter offset into account. With the right tools, users can also use shaping to chamfer edges up to special surface quality specs (beveling) or to engrave patterns into surfaces (engine turning) as is needed for printing technology or the jewelry and watchmaking industry.

At this year's EMO, HEIDENHAIN will present the cylindrical grinding functions for the TNC7 control for the first time. They further increase the potential of machining centers for done-in-one machining with milling, turning, and grinding on a single machine. Standardized cycles are available for cylindrical grinding as well as for the dressing of grinding wheels. The cycles support both the long-stroke and short-stroke grinding of rotationally symmetrical workpieces. In the process, reciprocating and infeed movements are performed independently of each other, thus making it possible to already optimize the machining process while proving-out, without needing to change the NC program. The cycles also automatically consider the machine kinematics regarding approach and departure movements, thereby helping users to deal with complex machines and challenging approach conditions.

The TNC7 and TNC7 basic also offer new cylinder surface machining capabilities. The cylinder surface transformation functionality now makes it possible to apply the already very comprehensive cycles for cylinder surface machining of nearly all milling, drilling, and engraving processes to a cylinder surface. To achieve this, the tool must be oriented perpendicularly to the rotary table axis and the cylindrical workpiece. When this transformation functionality has been activated, the user simply programs the required cycles and movements on the cylinder surface. During machining, the motion of the rotary table keeps the tool perpendicular to the cylinder surface.

Starting at EMO 2025, two new functions will complement the extensive simulation capabilities of the TNC7 controls and facilitate the verification of NC programs based on machine simulation. And by fast-forwarding and rewinding the tool path in the simulation, including the entire machine kinematics in the simulated TCP path, users can examine critical traverse movements in detail. The simulation report shows detected warnings and errors in a clear format, thus facilitating efficient and effective error analysis. Users can decide whether messages from the simulation are shown in the message menu of the information bar (as in the past) or in the Simulation report column in the Program workspace.

HEIDENHAIN is making the operation of handling robots on automated machine tools easier with a new solution: Users operate and program the robot directly via the TNC, without requiring any separate knowledge of robot control. This is possible because the movements of both the machine tool and the robot are programmed identically through the control's user interface. The robot is programmed via Klartext cycles, which is done very easily using the integrated teach-in processes. Users can incorporate various robot functions, such as pick-and-place, deburring, or gripper control, as desired. The robot control is connected to the TNC via Ethernet and does not require bus systems, meaning that this retrofitting is also very easy for legacy machines.

With the TNC7 go, HEIDENHAIN tailors the pioneering and intuitive user experience of the TNC7 family to vocational training applications and older machines, expanding on the practical functions that greatly simplify daily work. This particularly includes the new “graphical positioning” function. Instead of writing an NC program, the user draws the desired contours, patterns, or drilling positions directly on the touchscreen. The control then automatically handles their execution. Equally helpful are the new “Manual Cycles,” which enable typical machining tasks such as drilling or face milling without programming. With these features, the TNC7 go is just as ideal for anybody new to machine tools as it is for experienced professionals looking for fast results. The TNC7 go stands for efficient productivity, a short learning curve, and a user-friendly CNC experience. It is perfectly designed for the needs of state-of-the-art vocational training centers, shop floors, and machine upgrade projects.

www.heidenhain.com