www.ptreview.co.uk

04

'25

Written on Modified on

Jungheinrich Automates Packaging Logistics with High-Density Shuttle Warehouse

2,916 pallet locations, 24/7 multi-depth storage, real-time execution software and heavy-load shuttles enable centralised, scalable material flow from 2027.

www.jungheinrich.co.uk

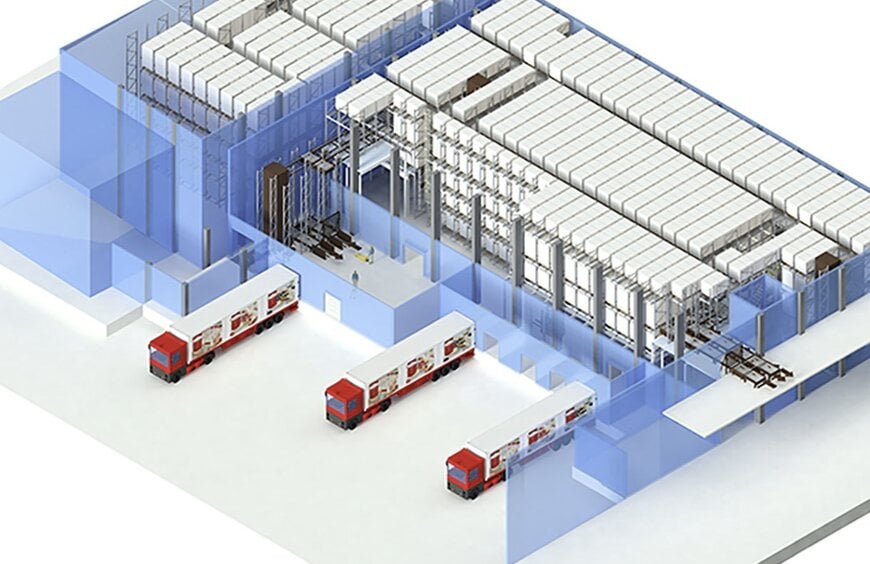

For food production and packaging logistics, Coppenrath & Wiese is implementing a fully automated warehouse at its Mettingen site to centralise previously decentralised packaging material storage. Delivered by Jungheinrich as a general contractor, the project consolidates all packaging logistics into one high-performance automated facility designed to significantly increase internal process efficiency.

High-Bay Shuttle Automation in Existing Buildings

The new warehouse spans two connected halls with heights of 11.66 metres and 12.76 metres and provides 2,916 pallet storage locations in a multi-depth configuration. Eight MOVU atlas pallet shuttles will operate around the clock, handling Euro and industrial pallets up to 1,000 kilograms as well as plastic and stainless-steel containers weighing up to 1,250 kilograms. The system enables automated transport across multiple building zones and levels.

With travel speeds of up to 1.4 m/s and acceleration of 0.4 m/s², the compact shuttles use dual independent wheel sets to navigate narrow storage channels with high positional accuracy. Their operating temperature range from -25°C to +45°C, allowing use in a wide variety of logistics environments.

Space Utilisation as a Competitive Advantage

By completely eliminating conventional driving aisles, the MOVU atlas shuttle system increases space utilisation by more than 50 percent compared to traditional warehouse layouts. This allows high storage density within the existing building footprint, avoiding costly structural expansion while creating reserve capacity for further volume growth.

Real-Time Software Control for End-to-End Automation

Warehouse operations are coordinated by the MOVU Warehouse Execution System, which synchronises material flow in real time across three functional control layers. Orders from the upstream warehouse management system are translated into transport tasks, optimally assigned to individual shuttles, and executed with precise motion control. The modular software architecture allows scalable expansion as throughput requirements increase.

Unlike isolated automation cells, this fully integrated software stack enables continuous transparency across transport, storage and retrieval processes, supporting stable performance under high dynamic loads.

Turnkey System Integration and Long-Term Operation

Jungheinrich delivers the complete system as a turnkey solution, including racking, platforms, stairways, safety equipment, pallet conveyor technology, vertical lifts, eight MOVU Atlas shuttles, the MOVU tower control layer, the MOVU ops warehouse management layer and full after-sales service. This end-to-end integration ensures coordinated performance across mechanical, digital and service components.

Warehouse operations are scheduled to begin in January 2027, positioning the Mettingen facility for long-term, scalable automation of packaging material logistics.

www.jungheinrich.com