www.ptreview.co.uk

19

'25

Written on Modified on

High-Speed CCD Line Sensor for Visual Inspection

The new Toshiba TCD2400DG targets colour line scan cameras with higher readout speed, simplified system integration, and reduced electromagnetic interference.

www.global.toshiba

Toshiba Electronic Devices & Storage Corporation has introduced the TCD2400DG, a colour CCD linear image sensor designed for line scan cameras used in high-speed visual inspection systems, with shipments commencing immediately.

Addressing performance limits in line scan inspection

Line scan cameras are widely used in inspection systems that must evaluate continuously moving objects, such as food products, recycled materials, and industrial components. In these applications, inspection accuracy depends on both spatial resolution and line rate, as objects pass the sensor at high speed and large image volumes must be processed in real time.

The TCD2400DG is positioned as a performance upgrade over Toshiba’s existing TCD2564DG sensor, specifically targeting higher throughput inspection equipment where readout speed has become a limiting factor.

Sensor architecture and imaging characteristics

The TCD2400DG is a CCD linear image sensor with 4,096 picture elements arranged in three independent lines, one each for red, green, and blue. The element pitch is 7 µm, a format widely adopted in industrial inspection cameras.

Each RGB line operates independently, enabling direct colour acquisition without the colour interpolation processing required by Bayer-pattern sensors. This architecture supports immediate colour judgment, which is critical in inspection systems where latency directly affects sorting accuracy and throughput.

Increased line rate for faster processing

The sensor supports a maximum line rate of 22.7 kHz, more than double the 10.5 kHz line rate of the earlier TCD2564DG. The higher readout speed allows inspection equipment to process objects moving at greater speeds or to increase inspection resolution without sacrificing throughput.

By increasing the number of lines captured per second, the sensor enables faster decision-making in applications such as colour sorting and defect detection, where inspection systems must keep pace with high-speed conveyors or web materials.

Integration and system-level simplification

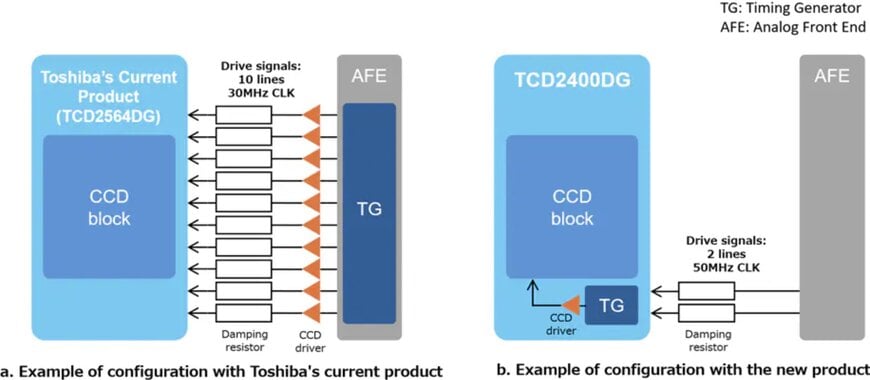

In contrast to Toshiba’s previous inspection sensors, the TCD2400DG integrates the timing generator circuit and CCD driver directly into the sensor package. Earlier designs required these components to be mounted externally, increasing system complexity and wiring requirements.

Integrating these functions reduces the number of external signal lines needed to drive the CCD and removes the need for an external CCD driver. This simplifies timing adjustment during system design and reduces development effort for camera and inspection equipment manufacturers.

Electromagnetic interference considerations

High-speed CCD operation can generate electromagnetic interference, particularly when multiple high-frequency signal lines are routed externally. By reducing external wiring, the TCD2400DG helps suppress EMI associated with high-speed operation.

Lower EMI contributes to more stable signal integrity in inspection systems, which is particularly relevant in industrial environments where sensors operate alongside motors, power electronics, and high-current machinery.

Comparison of number of drive terminals between TCD2400DG and Toshiba's current product

Target applications

The TCD2400DG is intended for colour line scan cameras used in sorting and inspection systems, including food sorting machines for grains and agricultural products, plastic pellet and recycled material sorting, web inspection of sheet materials such as paper, film, and textiles, and inspection of printed materials and industrial surfaces.

Position within industrial imaging development

With higher line rates, direct RGB acquisition, and integrated drive circuitry, the TCD2400DG reflects a broader trend toward simplifying camera system design while increasing inspection throughput. Within the industrial imaging and sensing market, such developments support more capable inspection systems without increasing system complexity, enabling faster and more reliable visual inspection across manufacturing and processing industries.

www.toshiba.semicon-storage.com