www.ptreview.co.uk

07

'26

Written on Modified on

Siemens Introduces Digital Twin Composer for Industrial Metaverse Environments

The new software connects real-time operational data with high-fidelity digital twins, enabling virtual validation of products, production systems, and facilities before physical implementation.

www.siemens.com

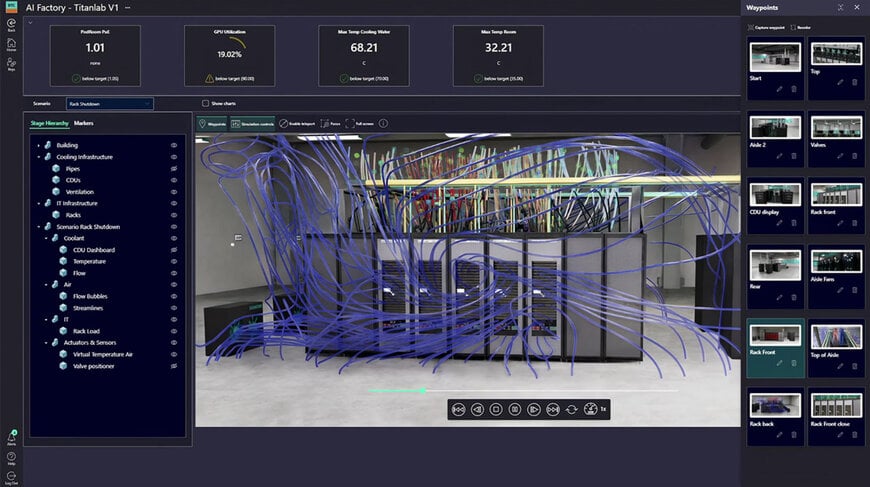

Siemens’ Digital Twin Composer builds Industrial Metaverse environments at scale, empowering organizations to apply industrial AI, simulation and real-time physical data to make decisions virtually, at speed and at scale

As industrial systems grow more complex, manufacturers are under increasing pressure to shorten design cycles, reduce capital risk, and manage tightly coupled engineering and operational data. Siemens has introduced Digital Twin Composer as a software layer designed to unify simulation, real-time physical data, and industrial AI within a single, continuously updated digital environment.

Digital Twin Composer is built to create and manage large-scale industrial metaverse environments by combining existing 2D and 3D digital twin assets with live operational inputs. Using NVIDIA Omniverse libraries, the software generates photorealistic, physics-accurate scenes that represent products, production lines, logistics flows, or entire facilities. These environments remain synchronized across the lifecycle of a product or plant, allowing organizations to evaluate decisions virtually before committing to physical changes.

By contextualizing real-time data within a high-fidelity digital twin, the platform enables engineers and operations teams to visualize system behavior, test configuration changes, and validate performance assumptions under realistic conditions. This approach supports applications ranging from factory layout planning and automation validation to equipment deployment and supply chain optimization.

A key objective of Digital Twin Composer is to reduce fragmentation between design, engineering, and operations teams. Many industrial organizations rely on separate tools and disconnected datasets for simulation, automation, and production management. Digital Twin Composer consolidates these domains into a single, managed environment, allowing stakeholders to work from a shared model that reflects both virtual designs and physical system states.

PepsiCo are digitally transforming select US manufacturing and warehouse facilities with the help of Digital Twin Composer (Image credit: PepsiCo)

The software integrates with Siemens Xcelerator, connecting digital twin models to manufacturing execution systems, quality management systems, programmable logic controllers, and industrial IoT data sources. Additional analytics and decision support can be layered through Siemens’ data science and AI software, including RapidMiner, enabling predictive and optimization-driven use cases within the virtual environment.

Early industrial adoption demonstrates the practical impact of this approach. PepsiCo is using Digital Twin Composer to transform selected manufacturing and warehouse facilities in the United States into high-fidelity digital twins. By simulating plant operations and end-to-end material flows, teams were able to validate new configurations within weeks, identify up to 90 percent of potential issues prior to physical implementation, and establish a reliable performance baseline. Initial deployments delivered a 20 percent throughput increase, near-complete design validation, and capital expenditure reductions of 10 to 15 percent by uncovering previously hidden capacity constraints.

By combining industrial-grade digital twins, real-time data integration, and physically accurate simulation, Digital Twin Composer positions the industrial metaverse as an operational tool rather than a conceptual model. The software enables manufacturers to evaluate complexity, reduce execution risk, and continuously optimize products and production systems within a controlled virtual environment before changes reach the factory floor.

www.siemens.com

As industrial systems grow more complex, manufacturers are under increasing pressure to shorten design cycles, reduce capital risk, and manage tightly coupled engineering and operational data. Siemens has introduced Digital Twin Composer as a software layer designed to unify simulation, real-time physical data, and industrial AI within a single, continuously updated digital environment.

Digital Twin Composer is built to create and manage large-scale industrial metaverse environments by combining existing 2D and 3D digital twin assets with live operational inputs. Using NVIDIA Omniverse libraries, the software generates photorealistic, physics-accurate scenes that represent products, production lines, logistics flows, or entire facilities. These environments remain synchronized across the lifecycle of a product or plant, allowing organizations to evaluate decisions virtually before committing to physical changes.

By contextualizing real-time data within a high-fidelity digital twin, the platform enables engineers and operations teams to visualize system behavior, test configuration changes, and validate performance assumptions under realistic conditions. This approach supports applications ranging from factory layout planning and automation validation to equipment deployment and supply chain optimization.

A key objective of Digital Twin Composer is to reduce fragmentation between design, engineering, and operations teams. Many industrial organizations rely on separate tools and disconnected datasets for simulation, automation, and production management. Digital Twin Composer consolidates these domains into a single, managed environment, allowing stakeholders to work from a shared model that reflects both virtual designs and physical system states.

PepsiCo are digitally transforming select US manufacturing and warehouse facilities with the help of Digital Twin Composer (Image credit: PepsiCo)

The software integrates with Siemens Xcelerator, connecting digital twin models to manufacturing execution systems, quality management systems, programmable logic controllers, and industrial IoT data sources. Additional analytics and decision support can be layered through Siemens’ data science and AI software, including RapidMiner, enabling predictive and optimization-driven use cases within the virtual environment.

Early industrial adoption demonstrates the practical impact of this approach. PepsiCo is using Digital Twin Composer to transform selected manufacturing and warehouse facilities in the United States into high-fidelity digital twins. By simulating plant operations and end-to-end material flows, teams were able to validate new configurations within weeks, identify up to 90 percent of potential issues prior to physical implementation, and establish a reliable performance baseline. Initial deployments delivered a 20 percent throughput increase, near-complete design validation, and capital expenditure reductions of 10 to 15 percent by uncovering previously hidden capacity constraints.

By combining industrial-grade digital twins, real-time data integration, and physically accurate simulation, Digital Twin Composer positions the industrial metaverse as an operational tool rather than a conceptual model. The software enables manufacturers to evaluate complexity, reduce execution risk, and continuously optimize products and production systems within a controlled virtual environment before changes reach the factory floor.

www.siemens.com