www.ptreview.co.uk

27

'26

Written on Modified on

Semi-Automated Bin Picking

A practical perspective from Ulrich Schäfer, Project Engineer at ZASCHE handling.

www.zasche.de

Manufacturers today face a growing operational balancing act. High-mix production, ongoing labour shortages, and increasingly strict safety and ergonomic requirements are placing pressure on both people and processes. Purely manual handling struggles to keep pace without increasing fatigue or injury risk, while fully automated systems are often costly, inflexible, and difficult to adapt to changing part variants. Between these two extremes lies a practical and increasingly attractive alternative: semi-automated bin picking.

Rather than replacing human involvement, semi-automated bin picking combines targeted automation with operator expertise. The approach transfers physically demanding, repetitive movements to machines while preserving human judgment, dexterity, and decision-making where they add the most value. For many manufacturers, this balance offers a realistic way to improve safety and productivity without committing to the complexity of full automation.

Shared work, complementary strengths

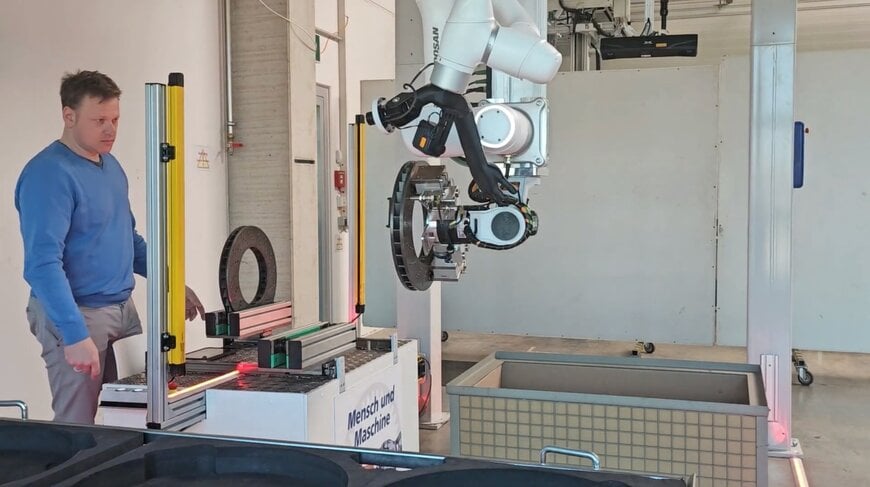

In semi-automated bin picking, components are retrieved directly from disordered containers. The system identifies part positions and supports controlled gripping and movement, while operators remain responsible for tasks that require perception, timing, or fine adjustment. The result is a collaborative workflow that leverages the respective strengths of people and machines.

This model addresses limitations on both ends of the automation spectrum. It reduces physical strain and repetitive lifting for operators, while avoiding the rigidity of fully robotic cells that often require extensive reprogramming when part geometries or batch sizes change. Because these systems are easier to adapt and redeploy, they are suitable not only for large-scale production, but also for smaller or more variable manufacturing environments.

Flexibility extends beyond the handling process itself. Semi-automated solutions typically tolerate mixed or loosely arranged parts, reducing the need for complex pre-sorting or custom containers. This simplifies upstream logistics and lowers overall system cost.

Human-centric automation in practice

What differentiates semi-automated bin picking from conventional robotic handling is its emphasis on keeping operators actively engaged. Automation provides lifting power, stability, and repeatability, while humans guide the process, manage exceptions, and ensure quality.

On the shop floor, this collaboration delivers tangible benefits. By removing the most physically demanding tasks, operators can focus on precision, coordination, and inspection. Fatigue is reduced, accuracy improves, and work becomes more sustainable over long shifts—without sacrificing control or responsiveness.

At the same time, semi-automated systems enable a combination of strength and finesse. Machines handle loads that would be impractical or unsafe manually, while final positioning and sensitive handling remain in human hands. This is particularly valuable in applications where delicate placement is just as critical as lifting capacity.

Adaptability further strengthens the concept. Modular grippers, configurable end-effectors, and intuitive control interfaces allow teams to accommodate new parts, layouts, or batch sizes with minimal disruption. Interaction can be as simple as push-button controls or as flexible as sensor-based or tablet-driven adjustments, depending on task complexity. Integrated sensing helps manage mixed or randomly oriented components without forcing the surrounding process to conform to rigid automation rules.

Incremental progress with real impact

Across industry, there is growing recognition that “smarter” does not always mean “fully automated.” Many of the most effective productivity gains come from targeted improvements rather than sweeping system replacements. Semi-automated bin picking exemplifies this approach—enhancing safety, efficiency, and flexibility while preserving operational resilience.

More importantly, it reinforces a perspective often overlooked in automation strategies. Meaningful progress does not have to be disruptive. When systems are designed to complement human capability instead of replacing it, the combination of machine endurance and human expertise becomes a competitive advantage.

As production environments continue to evolve, the key question is no longer whether automation should replace people, but how technology can extend human strengths while relieving them of tasks better suited to machines. Semi-automated bin picking offers a clear, practical answer—demonstrating how human skill and intelligent assistance can work together, not in competition, but in concert.

www.zasche.com