www.ptreview.co.uk

22

'23

Written on Modified on

SCHUNK INTRODUCES NEW GENERATION OF LINEAR DIRECT AXES WITH THE SLD SERIES

The dynamic, heavy-duty axes with electric linear direct drive ensure short cycle times and more productivity in high-speed assembly and handling processes for the electronics manufacturing, e-mobility or life science sectors.

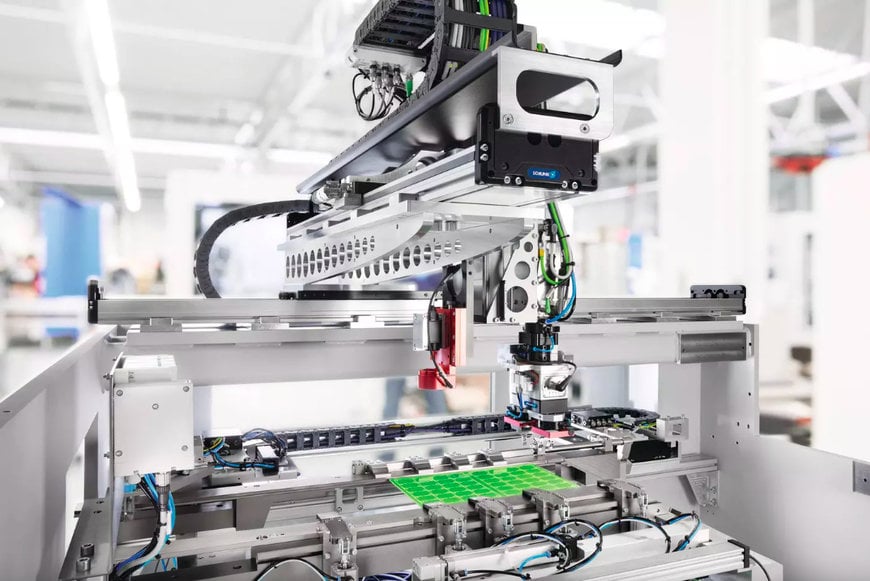

There is a wide range of applications for the linear SLD direct axes from SCHUNK. In the electronics industry, for example, it is used for depaneling and handling of printed circuit boards from panels.

The SLD series was developed as a dynamic all-rounder that can meet the requirements for higher basic load ratings and longer service life. At the same time, SCHUNK the automation expert is expanding its portfolio of linear direct axes with this series, and due to its modular design also enables an attractive price/performance ratio. For a wide range of applications, two sizes are currently available that have four different motor sizes each and that provide driving forces up to a maximum of 2,4 kN and load ratings of up to 106 kN. Additional versions will follow.

The electric drive and the path measuring system are already integrated into the compact axis, enabling agile, space-saving motion sequences. Accelerations of the direct drive up to 100 m/s² and speeds of 5 m/s ensure high dynamics and short cycle times. At the same time, the drive ensures an accuracy of ±0.01 mm for the user. Its elements operate without mechanical play, which eliminates wear parts and keeps maintenance costs to a minimum. In addition, the drive can be designed at any length without compromising performance. The linear direct axes of the SLD series are UL-certified as standard. This is the prerequisite for rapid access to the US market and other markets.

Options potentiate the range of applications

As a crucial component of the SLD axes, the profile rail guide enables the compact design and the absorption of high loads. Strokes of up to 6,000 mm can be achieved. On top of preventing the penetration of dirt and dust inside the axis, the use of a cover also makes applications in areas with coarse, sharp-edged or hot foreign bodies possible. This even paves the path for use in harsh environments. The cover also prevents grease from leaking with overhead assemblies.

SCHUNK offers the series a wide selection of options, including a holding brake that prevents gravity-loaded axes from dropping or falling unintentionally. This ensures safety in the applications. Mounted under the slide and pneumatically actuated, the brake reliably engages in the event of a power failure. In addition, the linear direct axes use a modular encoder system with the proven interfaces Hiperface/HiperfaceDSL, DRIVE-CLiQ, Sin/Cos and SSI. All encoders are also available in SIL2/PLd. Customized measuring systems can also be integrated on request.

The series SLD offers a whole range of options when it comes to mounting, installation, and combinations. This means that the linear direct axes can be easily combined using an adapter plate, fastened by clamps and used in a variety of applications. Due to its high dynamics, load rating and long service life, the axis is ideal for industries ranging from electronics and electrical engineering, food and packaging, life science and assembly automation, and on to photovoltaics and automotive engineering. In e-mobility, for example, the handling of prismatic cells can be implemented just as efficiently as in hairpin applications with high demands on flexibility, dynamics and precision. For easy configuration and design of its electric linear axes, SCHUNK is expanding its digital services and plans to launch a practical configurator this year.

The SLD series was developed as a dynamic all-rounder that can meet the requirements for higher basic load ratings and longer service life. At the same time, SCHUNK the automation expert is expanding its portfolio of linear direct axes with this series, and due to its modular design also enables an attractive price/performance ratio. For a wide range of applications, two sizes are currently available that have four different motor sizes each and that provide driving forces up to a maximum of 2,4 kN and load ratings of up to 106 kN. Additional versions will follow.

The electric drive and the path measuring system are already integrated into the compact axis, enabling agile, space-saving motion sequences. Accelerations of the direct drive up to 100 m/s² and speeds of 5 m/s ensure high dynamics and short cycle times. At the same time, the drive ensures an accuracy of ±0.01 mm for the user. Its elements operate without mechanical play, which eliminates wear parts and keeps maintenance costs to a minimum. In addition, the drive can be designed at any length without compromising performance. The linear direct axes of the SLD series are UL-certified as standard. This is the prerequisite for rapid access to the US market and other markets.

Options potentiate the range of applications

As a crucial component of the SLD axes, the profile rail guide enables the compact design and the absorption of high loads. Strokes of up to 6,000 mm can be achieved. On top of preventing the penetration of dirt and dust inside the axis, the use of a cover also makes applications in areas with coarse, sharp-edged or hot foreign bodies possible. This even paves the path for use in harsh environments. The cover also prevents grease from leaking with overhead assemblies.

SCHUNK offers the series a wide selection of options, including a holding brake that prevents gravity-loaded axes from dropping or falling unintentionally. This ensures safety in the applications. Mounted under the slide and pneumatically actuated, the brake reliably engages in the event of a power failure. In addition, the linear direct axes use a modular encoder system with the proven interfaces Hiperface/HiperfaceDSL, DRIVE-CLiQ, Sin/Cos and SSI. All encoders are also available in SIL2/PLd. Customized measuring systems can also be integrated on request.

The series SLD offers a whole range of options when it comes to mounting, installation, and combinations. This means that the linear direct axes can be easily combined using an adapter plate, fastened by clamps and used in a variety of applications. Due to its high dynamics, load rating and long service life, the axis is ideal for industries ranging from electronics and electrical engineering, food and packaging, life science and assembly automation, and on to photovoltaics and automotive engineering. In e-mobility, for example, the handling of prismatic cells can be implemented just as efficiently as in hairpin applications with high demands on flexibility, dynamics and precision. For easy configuration and design of its electric linear axes, SCHUNK is expanding its digital services and plans to launch a practical configurator this year.

www.schunk.com