www.ptreview.co.uk

01

'23

Written on Modified on

CONTRINEX PRESENTS NO-CODE SENSOR CONFIGURATOR FOR INDUSTRIAL PCB VARIANT IDENTIFICATION

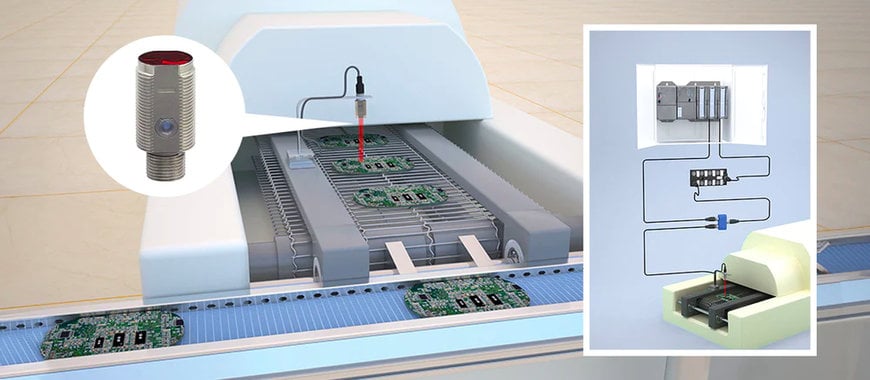

No-contact photoelectric smart sensors identify industrial PCB variants in real-time, eliminating downstream assembly errors.

High-volume assembly operations rely on continuous flow of parts and materials to maintain optimum throughput levels. Multiple variants of individual parts, routed via common feeder lines, require real-time identification to ensure on-time delivery to the correct assembly areas.

Industrial-control-equipment manufacturers trust Contrinex no-contact DMS photoelectric Smart Sensors to detect variant-specific components on conveyor-fed PCB assemblies, diverting each PCB to its designated assembly line. Using the no-code PocketCodr sensor configurator to teach multiple detection setpoints minimizes set-up time and associated commissioning costs.

Advantages at a glance

- No-contact DMS photoelectric Smart Sensors eliminate costly downstream assembly errors.

- In-line identification of multiple PCB variants supports continuous-flow production and reduces inventory costs.

- No-code PocketCodr sensor configurator teaches detection setpoints using live targets, minimizing set-up and commissioning costs.