www.ptreview.co.uk

03

'25

Written on Modified on

Dunkermotoren introduces dSafe integrated functional safety for BG motor series

dSafe integrates STO, SS1, SLS, SBC, and safe communication into BG75/BG95 motors, meeting IEC 61800, 13849, 62061, 61508 standards.

www.dunkermotoren.com

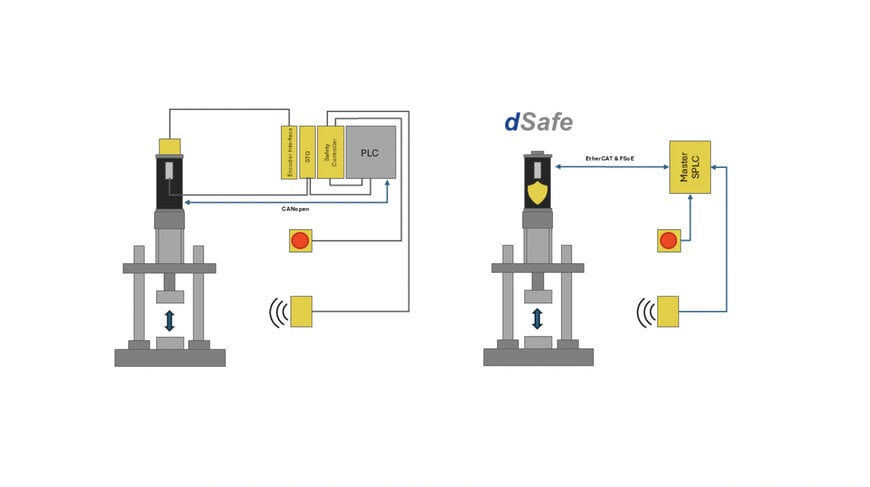

Dunkermotoren unveils its latest innovation: dSafe, a cutting-edge product line that sets new standards for integrated functional safety in motor drive systems. Expanding on the existing portfolio (dGo, dMove, dPro), dSafe brings advanced safety features like secure communication and safe motion profiles—fully embedded into the BG75 and BG95 brushless DC motor series.

Maximum Safety, minimal Effort

Built to meet international safety standards (IEC 61800, IEC 13849, IEC 62061, IEC 61508), dSafe includes essential features such as:

- Safe Torque Off (STO)

- Safe Stop (SS1)

- Safely Limited Speed (SLS)

- Safe Brake Control (SBC)

- Safe Communication (FSoE, PROFIsafe)

This seamless integration not only reduces hardware complexity but also simplifies safety assessments for machine builders.

Versatile applications across industries

dSafe-is designed for a wide range of applications—from industrial automation and robotics to warehouse logistics, access systems, and packaging machinery. In mobile robots (AGVs/AMRs), it enables a flexible, online-configurable safety architecture with multiple safety layers—protecting drive functions, lifting mechanisms, and grippers.

The “Safe Limited Speed” (SLS) feature automatically slows down the motor when people or obstacles are nearby, enhancing safety in collaborative environments.

In stationary industrial setups, dSafe offers clear advantages during setup and maintenance. Reduced speeds via SLS ensure safe handling, while “Safe Limited Position” (SLP) allows for the creation of defined safety zones, limiting the movement of axes or tools.

Another major benefit: the traditional hardwiring of STO can be eliminated. Safe shutdowns are now possible via fieldbus systems like FSoE—saving wiring effort, increasing layout flexibility, and streamlining integration into modern control architectures.

Customer Value that Pays Off

By embedding safety features directly into the motor, dSafe delivers significant cost and efficiency benefits:

Versatile applications across industries

dSafe-is designed for a wide range of applications—from industrial automation and robotics to warehouse logistics, access systems, and packaging machinery. In mobile robots (AGVs/AMRs), it enables a flexible, online-configurable safety architecture with multiple safety layers—protecting drive functions, lifting mechanisms, and grippers.

The “Safe Limited Speed” (SLS) feature automatically slows down the motor when people or obstacles are nearby, enhancing safety in collaborative environments.

In stationary industrial setups, dSafe offers clear advantages during setup and maintenance. Reduced speeds via SLS ensure safe handling, while “Safe Limited Position” (SLP) allows for the creation of defined safety zones, limiting the movement of axes or tools.

Another major benefit: the traditional hardwiring of STO can be eliminated. Safe shutdowns are now possible via fieldbus systems like FSoE—saving wiring effort, increasing layout flexibility, and streamlining integration into modern control architectures.

Customer Value that Pays Off

By embedding safety features directly into the motor, dSafe delivers significant cost and efficiency benefits:

- Less engineering effort

- Reduced cabling

- Faster commissioning

- Lower hardware costs

- Reduced total cost of ownership (TCO)

Future-Proof and Modular

With support for EtherCAT/FSoE and PROFINET/PROFIsafe, dSafe is built for scalable, high-performance safety architectures. It’s a future-ready solution for demanding applications.

www.dunkermotoren.com

With support for EtherCAT/FSoE and PROFINET/PROFIsafe, dSafe is built for scalable, high-performance safety architectures. It’s a future-ready solution for demanding applications.

www.dunkermotoren.com